Made in America

Get Connected With

Email Us

sale@abrvpartsacc.com

Call Us

+1 (626) 448-2100

Made in America

Get Connected With

Stainless steel fittings play a crucial role in various industries. These fittings are essential components used for connecting pipes and tubes. They provide durability, corrosion resistance, and strength. Understanding the different types of stainless steel fittings is important for making informed decisions.

There are various applications for stainless steel fittings. They are commonly found in plumbing, automotive, and industrial settings. Choosing the right fitting requires knowledge of their specifications and uses. However, many users overlook critical details. This can lead to costly mistakes or unsafe installations.

Exploring the world of stainless steel fittings reveals much complexity. Some people may find it challenging to navigate the options available. It is essential to recognize instances where the wrong choice could weaken a system. Learning about these fittings can prevent such issues. The goal is to achieve reliability and efficiency in every application.

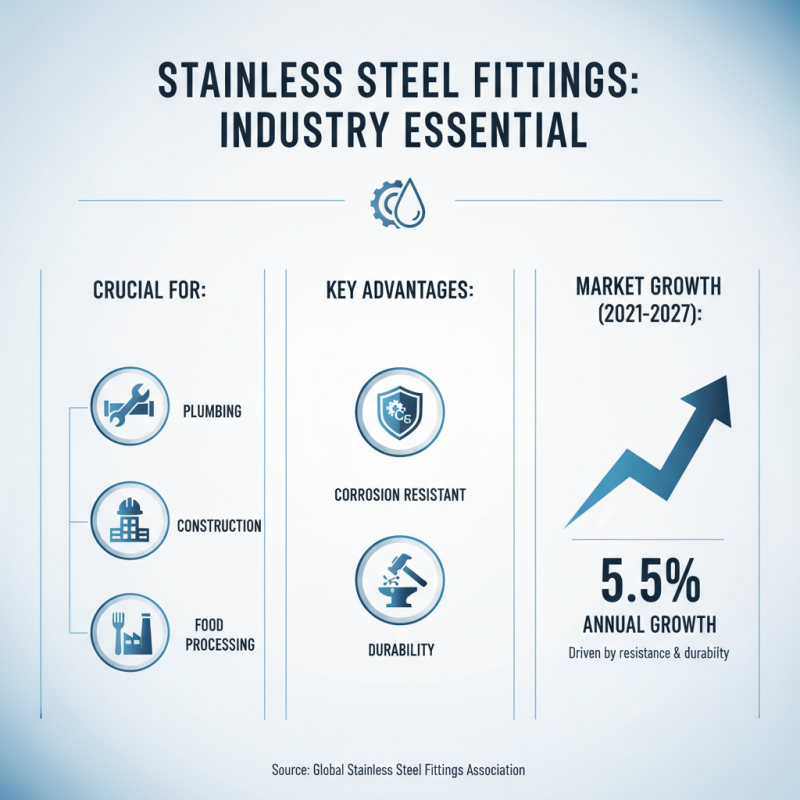

Stainless steel fittings play a crucial role in various industries. They are vital for plumbing, construction, and even food processing. According to a market research report by the Global Stainless Steel Fittings Association, the demand for stainless steel fittings is projected to grow at a rate of 5.5% annually from 2021 to 2027. This growth is driven by their resistance to corrosion and durability.

There are several types of stainless steel fittings, including flanges, elbows, and tees. Each type serves a specific purpose and is essential in different applications. For instance, elbows are used to change the direction of piping systems. Such fittings ensure efficient fluid flow in both residential and industrial settings. Interestingly, 40% of plumbing failures are related to poor-quality fittings, highlighting the need for reliable options.

Benefits of stainless steel fittings extend beyond their longevity. They also provide a clean and aesthetic finish, especially in visible plumbing areas. Their ability to withstand extreme temperatures adds to their versatility. However, there are still challenges. For example, cost can be a concern, as stainless steel fittings tend to be pricier than their alternatives. This factor can deter small businesses from choosing them, despite their long-term benefits.

Stainless steel fittings come in various types, each serving specific functions. The most common types include

tees, elbows,

reducers, and couplings.

Each fitting has unique characteristics. For instance, tees allow for the branching of pipes. Elbows help in

changing direction. Reducers adjust pipe sizes, while couplings connect sections.

When selecting fittings, consider your project’s requirements. Think about the flow direction and pressure.

A wrong choice can affect performance. It's important to understand

that not every fitting is suitable for every application. Always review material compatibility. Some stainless

steel grades resist corrosion better than others.

Tips: Regularly inspect your fittings for any signs of wear. This can help prevent leaks and

failures. If you’re unsure about sizes, consult project guidelines. Proper measurements save time and materials.

Be cautious of installation mistakes; they can lead to costly repairs. Remember, even small errors can have

a significant impact.

Stainless steel fittings play a vital role in many industries. In the construction sector, they are used for plumbing and piping systems. Their resistance to corrosion makes them ideal for long-term use. In food processing, stainless steel fittings ensure hygiene. They withstand high temperatures and pressures, maintaining product integrity. However, sometimes the cost can be a concern, leading to budget constraints.

In the oil and gas industry, these fittings are crucial. They help connect pipelines and equipment. The high strength of stainless steel ensures safety in extreme conditions. Yet, installation errors can occur if not handled properly. This can lead to leaks and costly repairs.

The automotive industry also benefits from stainless steel fittings. They are used in machinery and exhaust systems. These applications require durability and reliability. Still, the complexity of designs can pose challenges. This makes it essential for engineers to double-check their work. Overall, these fittings represent a balance between innovation and practicality in various sectors.

When selecting stainless steel fittings, several critical factors come into play. Material grade is a top consideration. Different grades offer varying levels of corrosion resistance. For instance, 316 stainless steel has excellent resistance to pitting in chloride environments, making it suitable for marine applications. According to industry reports, using the wrong grade can lead to premature failure and increased maintenance costs.

Another vital aspect is the fitting type. Options include elbows, tees, and flanges. Each type serves a unique function in piping systems. Ensuring compatibility with the system is essential. This helps to avoid leaks and other issues. Data from market studies indicate that about 30% of fitting failures arise from improper selection.

Tips for choosing fittings:

- Always assess the environment where the fitting will be used.

- Do not overlook dimension standards.

- Ensure the fit is tight but not overly so; this can compromise the seal.

Consider the manufacturing process, too. Some fittings are forged, while others are cast. Forged fittings typically offer better strength and durability. Reflect on the application to determine the best method. An ill-informed choice can lead to significant setbacks in project timelines.

| Fitting Type | Material Grade | Common Applications | Pressure Rating | Corrosion Resistance |

|---|---|---|---|---|

| Elbow | 304 | Piping Systems, Plumbing | 150 PSI | Good |

| Tee | 316 | Chemical Processing, Oil and Gas | 200 PSI | Excellent |

| Coupling | 304 | Mechanical Connections | 150 PSI | Good |

| Cap | 316 | End of Pipes | 200 PSI | Excellent |

| Flange | 304L | Industrial Applications | 300 PSI | Very Good |

Maintaining stainless steel fittings requires attention to detail. Regular inspection is crucial. Look for signs of corrosion or wear. Cleaning should be done with a suitable solution. Use a soft cloth to avoid scratching the surface.

It's easy to overlook small issues. For instance, a loose connection can lead to leaks over time. Tightening fittings periodically helps prevent this. Also, be cautious with harsh chemicals. These can damage stainless steel. A gentle scrub often works best.

When storing fittings, keep them dry. Moisture can lead to rust. Proper organization can also help avoid damage. Don’t just toss them in a drawer. Use bins or racks instead. Invest time in maintenance practices. This can extend the lifespan of your stainless steel fittings significantly.