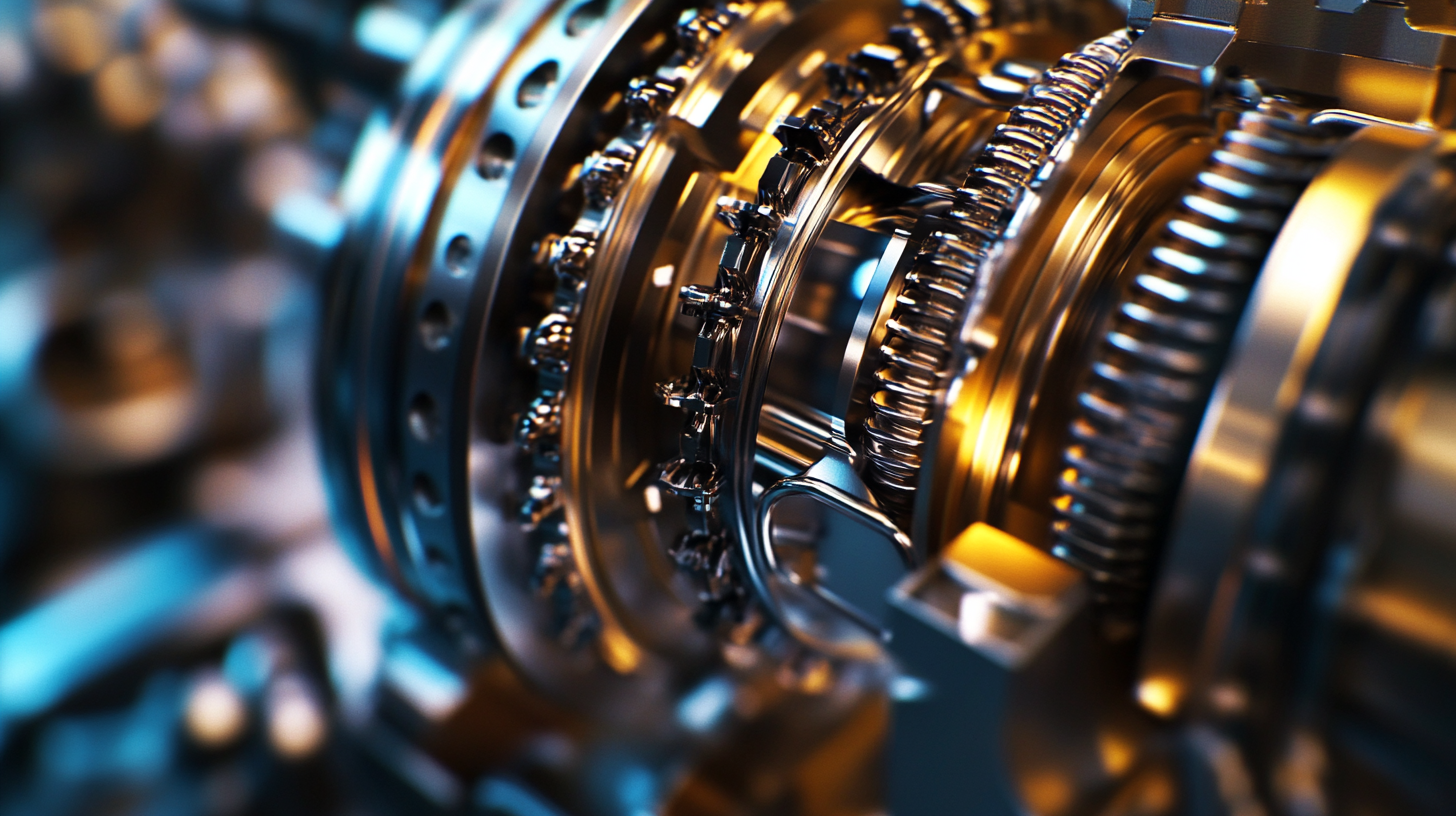

In the rapidly evolving landscape of global supply chains, the significance of quality components cannot be overstated, particularly when it comes to Hydraulic Gear Pump Parts. As we approach 2025, the dynamics of the industry are shifting, driven by advancements in technology and the growing demand for efficiency. This blog explores how China is revolutionizing the manufacturing of Hydraulic Gear Pump Parts, setting new standards that not only enhance performance but also address the challenges faced by businesses worldwide.

By delving into emerging trends and presenting innovative solutions, we aim to provide valuable insights for stakeholders looking to optimize their supply chain operations. Join us as we uncover the latest developments and discover how leveraging high-quality hydraulic gear pump components is key to success in a competitive market.

In recent years, China has emerged as a powerhouse in the manufacturing of hydraulic gear pump parts, leveraging innovative techniques that elevate the efficiency and quality of production.

The country's commitment to integrating advanced technologies in its manufacturing processes is reshaping the landscape of hydraulic components. With a focus on automation and precision engineering, Chinese manufacturers are not only enhancing productivity but also ensuring that the parts meet the stringent requirements of global markets.

The growth of the hydraulic pumps market, projected to surge significantly from 2025 to 2035, underscores the increasing need for high-quality pump parts. As industries worldwide seek reliable hydraulic systems to boost operational efficiency, the innovative manufacturing techniques developed in China are making their mark.

From employing cutting-edge materials to utilizing smart manufacturing solutions, China is setting new standards for hydraulic gear pump production, promising enhanced durability and performance for users around the globe. This evolution in manufacturing capabilities positions China as a key player in the advancement of hydraulic technology and supply chains.

In today’s fast-paced industrial landscape, supply chain efficiency is paramount. The integration of high-quality hydraulic gear pump parts from Chinese manufacturers has emerged as a game-changer for businesses aiming to streamline their operations. Chinese hydraulic component providers are not only known for their cost-effective solutions but also for their advanced manufacturing technologies and rigorous quality control processes. This combination allows companies to enhance performance, reduce downtime, and ultimately boost their bottom line.

Moreover, the accessibility of these parts has transformed traditional supply chains into more responsive and agile frameworks. With the capability to quickly source and adapt components, businesses can better meet customer demands and respond to market fluctuations. This agility not only helps maintain a competitive edge but also fosters stronger relationships with clients who value reliability and efficiency. By leveraging the innovative offerings from Chinese suppliers, companies can revolutionize their supply chains, positioning themselves for long-term success in an increasingly globalized market.

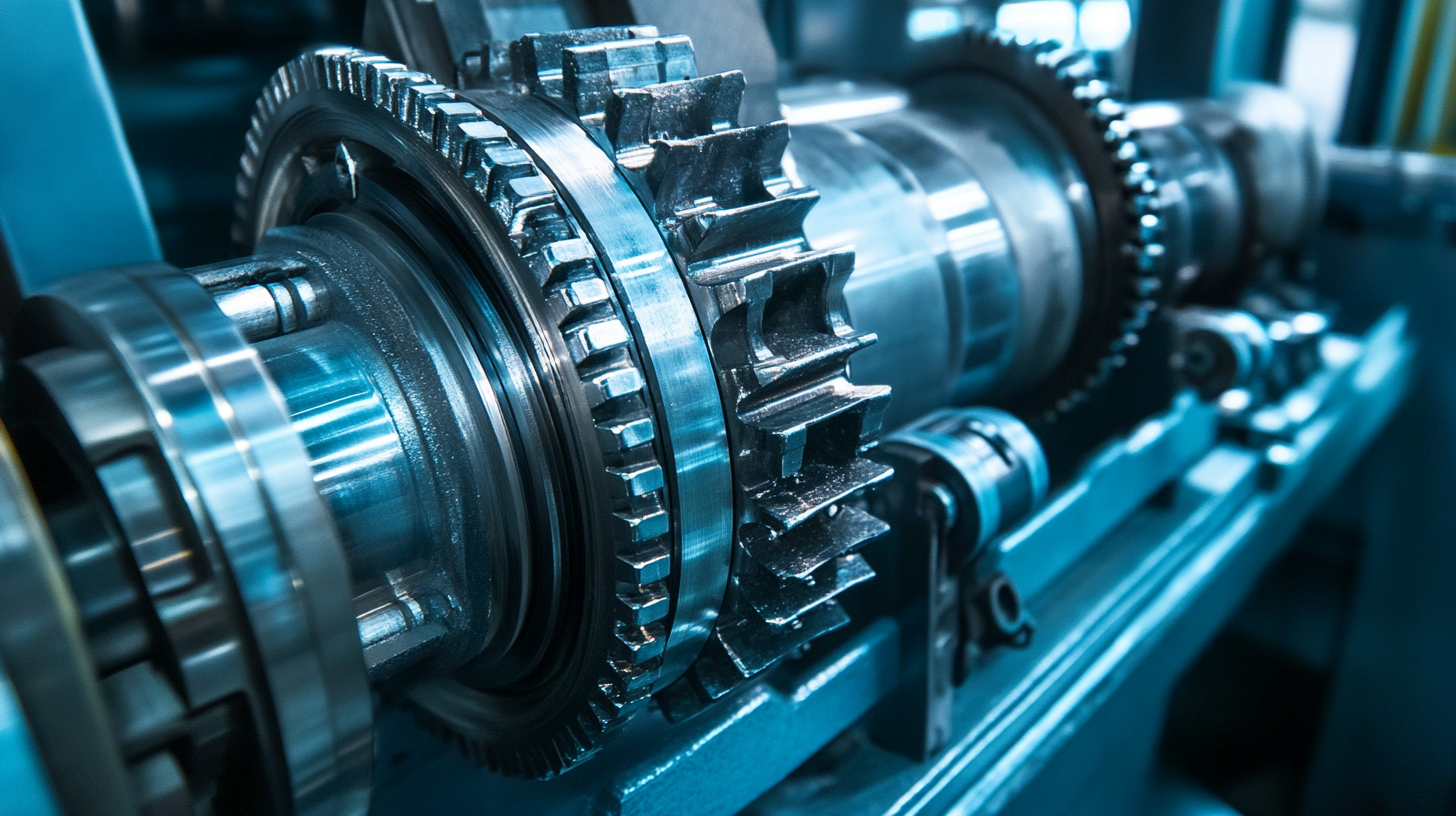

In the rapidly evolving landscape of global supply chains, quality control has become a cornerstone of successful manufacturing, especially in the production of hydraulic gear pump parts. China, known for its robust manufacturing capabilities, has implemented rigorous quality control practices that ensure the reliability and performance of its hydraulic components. These practices include stringent material selection, precise machining processes, and comprehensive testing protocols, which collectively elevate the standard of hydraulic gear pumps produced in the country.

At the heart of China’s quality control practices is a commitment to continuous improvement and adherence to international standards. Manufacturers often employ advanced technologies such as automated inspection systems and real-time monitoring to detect defects early in the production process. Additionally, many companies prioritize training their workforce, equipping employees with the skills needed to maintain high-quality outcomes consistently. This focus on quality not only enhances product performance but also builds trust with global partners seeking durable and efficient hydraulic gear pump parts.

The world of hydraulic components is undergoing a remarkable transformation, especially in China, where technology and automation are reshaping the production landscape. By leveraging advanced manufacturing techniques such as robotics, IoT, and AI, Chinese factories are not just enhancing efficiency but also improving the precision and quality of hydraulic gear pump parts. This integration of technology allows manufacturers to respond swiftly to market demands while maintaining consistency in their products.

Automation plays a crucial role in optimizing production lines, reducing labor costs, and minimizing human error. With smart machinery and predictive maintenance systems, manufacturers can anticipate equipment failures and reduce downtime, leading to seamless production cycles. This results in a higher output of hydraulic parts that meet international standards, ultimately revolutionizing global supply chains. As industries increasingly rely on these components, the availability of high-quality hydraulic gear pump parts from China ensures they can operate at peak performance, solidifying China's position as a leader in the hydraulic parts market.

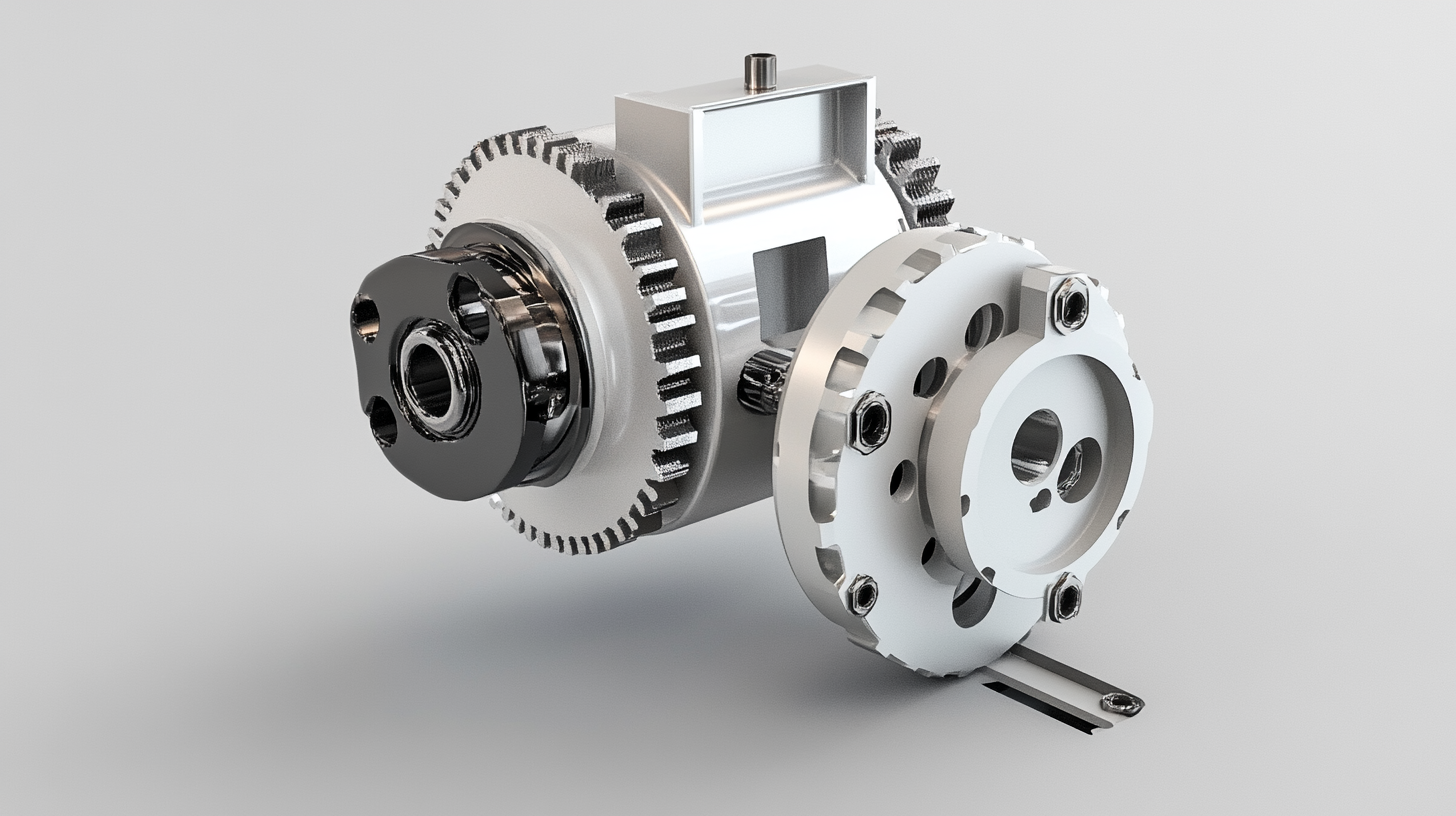

As global industries continue to innovate and evolve, the hydraulic gear pump sector is experiencing tremendous growth, driven largely by advancements in manufacturing capabilities in China. According to a report by Research and Markets, the global hydraulic pump market is projected to reach $22.53 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.1%. This surge underscores the increasing reliance of international businesses on high-quality, cost-effective hydraulic components, particularly those produced in China.

Building stronger global partnerships is vital for leveraging this growth in hydraulic gear pumps. Chinese manufacturers have established themselves as key players by implementing state-of-the-art technology and adhering to stringent quality standards. By fostering collaborative relationships with international companies, they not only ensure a steady supply of hydraulic gear pumps but also enhance technological exchanges and innovation. For instance, companies like Bosch Rexroth have reported that integrating Chinese suppliers into their networks has fueled operational efficiency, leading to a significant reduction in lead times and production costs. As these partnerships expand, they pave the way for a more resilient and interconnected global supply chain, essential for meeting the \ ever-growing demands of various industries worldwide.