Made in America

Get Connected With

Email Us

sale@abrvpartsacc.com

Call Us

+1 (626) 448-2100

Made in America

Get Connected With

Pipe joints play a crucial role in the stability and performance of piping systems across various industries, from oil and gas to chemical manufacturing. According to a report by the American Society of Mechanical Engineers (ASME), approximately 30% of pipeline failures can be directly traced back to inadequate joint design or installation. These joints not only facilitate the connection between different segments of piping systems but also accommodate thermal expansion, vibrations, and potential misalignments, all of which are critical factors that can compromise system integrity.

The importance of using reliable and properly designed pipe joints becomes even more evident when considering the industry's growing focus on safety and efficiency. The National Fire Protection Association (NFPA) notes that improper installation and maintenance of pipe joints are significant contributors to hazardous material leaks and fires. As industries increasingly adopt stringent regulations to mitigate risks, investing in high-quality pipe joints has become essential. This proactive measure not only helps ensure compliance with safety standards but also prolongs the life of the piping system, ultimately leading to lower maintenance costs and enhanced operational efficiency.

Pipe joints play a critical role in ensuring the safety and efficiency of piping systems. According to a report by the American Society of Mechanical Engineers (ASME), approximately 30% of industrial piping failures are attributed to inadequate or improperly installed joints. This highlights the importance of selecting the right materials and methods for joining pipes, as even minor errors can lead to significant leaks, increased maintenance costs, and potentially hazardous situations.

Additionally, a comprehensive study published in the Journal of Constructional Steel Research indicates that well-designed pipe joints can increase the overall lifespan of a piping system by up to 50%. Properly sealed joints minimize the risk of corrosion and wear, which are common issues in various industrial environments. Investing in robust pipe joints not only ensures operational efficiency but also contributes to the sustainability of piping infrastructure, reducing waste and energy consumption over time. As such, the integration of high-quality joints is vital for any successful piping system.

Pipe joints are crucial components in piping systems, serving various applications across different industries. Understanding the types of pipe joints available can greatly enhance the safety and efficiency of these systems. In water supply and distribution, for instance, PVC pipe joints, including UPVC and CPVC, offer excellent resistance to corrosion and chemicals. These joints ensure reliable connectivity among pipes, reducing the risk of leaks and pressure loss.

In HVACR and plumbing applications, copper pipe joints, such as Type K, Type L, and Type M connections, are widely utilized. These joints are favored for their durability and thermal conductivity, which are essential for efficient heat transfer in heating and cooling systems. Additionally, reducing tee connectors play a vital role in managing flow direction and pressure within pipe networks, enabling seamless transitions between different pipe sizes. The increasing demand for these joints is reflected in market growth projections, highlighting their essential role in infrastructure development and maintenance.

| Type of Pipe Joint | Material | Common Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Welded Joint | Steel | Oil and Gas, Water Supply | Strong, Permanent Seal | Requires Skilled Labor, Difficult to Dismantle |

| Flanged Joint | Cast Iron, Steel | Water Treatment, Chemical Processing | Easily Removable, Versatile | Bulkier, Potential for Leakage |

| Screwed Joint | Brass, Steel | Plumbing, HVAC | Simple Installation, Cost-Effective | Limited to Smaller Pipes, Vulnerable to Vibration |

| Mechanical Joint | PVC, Ductile Iron | Water Distribution, Wastewater | Easy to Install and Repair | May Not Handle High Pressure |

| Coupled Joint | Flexible PVC, Rubber | Irrigation, Drainage | Flexibility, Easy to Assemble | Not Suitable for High-Pressure Systems |

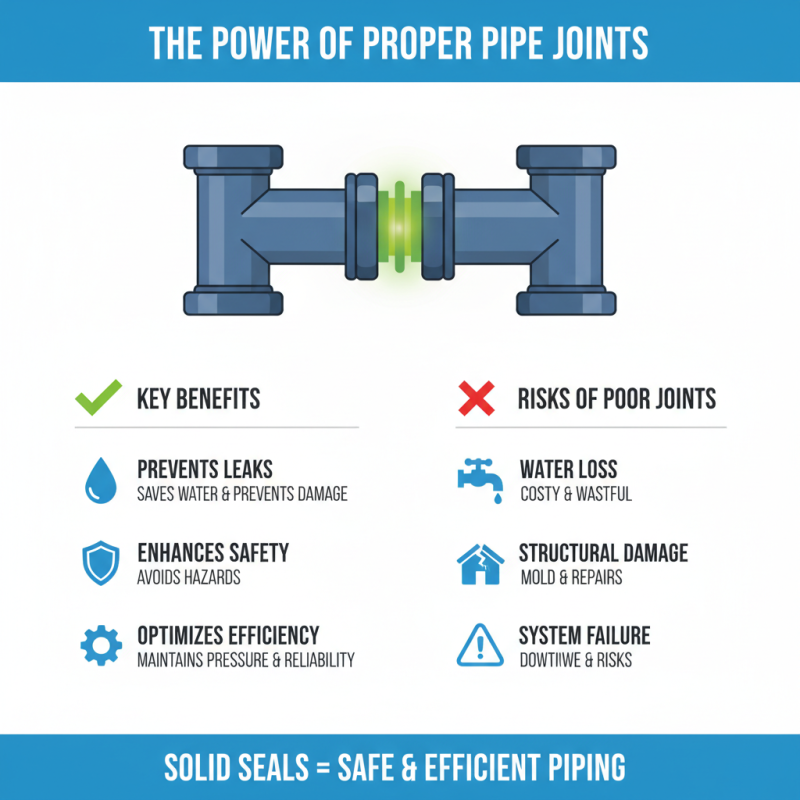

Properly installed pipe joints are crucial for the overall safety and efficiency of piping systems. One of the primary benefits is the prevention of leaks, which can lead to significant water loss, damage, or even hazardous situations. High-quality joints create a solid seal that helps maintain pressure within the system, ensuring reliable operation.

Tips: When installing pipe joints, always ensure that the surfaces are clean and well-prepared to achieve a tight fit. Additionally, selecting the right type of joint for your specific application can further enhance performance and longevity.

Another key advantage of well-installed pipe joints is their ability to absorb vibrations and thermal expansions. This flexibility minimizes stress on the pipes, reducing the risk of failure over time. By incorporating expansion joints or flexible connectors as part of the piping design, you can improve system adaptability and durability.

Tips: Regularly inspect pipe joints for signs of wear or loosening. Using proper installation techniques and tools will help to maintain their integrity over time and prevent costly repairs.

Maintaining pipe joints is crucial for the longevity and safety of piping systems. Common challenges include corrosion, improper installation, and joint fatigue. According to a report by the American Society of Mechanical Engineers (ASME), nearly 30% of industrial piping failures can be attributed to joint issues. Regular inspections and maintenance are vital to preventing these costly breakdowns. For instance, utilizing advanced leak detection technologies can identify weak points in joints before they lead to significant failures.

Tip: Conduct regular visual inspections and utilize corrosion inhibitors to extend the lifespan of pipe joints.

Another frequent challenge is ensuring proper torque and alignment during installation. The American Petroleum Institute (API) states that misaligned joints can increase stress and lead to premature failure. Implementing standardized training for maintenance personnel can mitigate this risk. Additionally, using joint alignment tools can improve installation accuracy and reduce the likelihood of future leaks.

Tip: Always follow manufacturer specifications for torque settings and alignment during installation for optimal performance.

Pipe joints play a crucial role in maintaining the integrity and safety of piping systems. Adhering to safety standards and regulations is essential to ensure that these joints can withstand the various stresses they encounter. Regulatory bodies set specific guidelines that dictate how pipe joints should be designed, tested, and maintained to prevent leaks, failures, and accidents that could endanger lives and the environment. Compliance with these regulations helps assure that materials used are suitable for the intended application and that installation practices meet required safety criteria.

Furthermore, the integrity of pipe joints is regularly assessed through inspections and testing protocols. Many industries, including oil and gas, chemicals, and water utilities, must follow stringent safety measures to qualify their piping systems. Regular maintenance and periodic assessments are necessary to detect any signs of wear, corrosion, or deterioration that could compromise joint integrity. By prioritizing these regulations and safety standards, organizations can minimize risks associated with piping systems and enhance operational efficiency.

This chart illustrates the compliance rates of various safety standards that govern pipe joint integrity. Ensuring that piping systems meet these standards is crucial for both safety and efficiency in operations.