Made in America

Get Connected With

Email Us

sale@abrvpartsacc.com

Call Us

+1 (626) 448-2100

Made in America

Get Connected With

In the intricate world of plumbing systems, the significance of pipe joints cannot be overstated. These vital components serve as the connections between various lengths of piping, ensuring a seamless flow of water or other fluids throughout a building's infrastructure. Understanding what pipe joints are and how they operate is essential for anyone involved in plumbing maintenance, installation, or repairs, as they play a crucial role in maintaining the integrity and efficiency of the system.

Pipe joints come in various forms, each designed to accommodate specific functions and movement allowances. Their construction often involves materials that can withstand various pressures and temperatures, making them resilient against leaks and damages. As plumbing systems encounter stresses from thermal expansion, water pressure, and environmental factors, the proper selection and installation of pipe joints become paramount to ensuring long-term reliability. This introduction aims to explore the functions, types, and operational mechanics of pipe joints within plumbing systems, shedding light on their pivotal role in modern infrastructure.

A pipe joint is an essential component in plumbing systems, serving as the connection point between different sections of pipes. This joint enables the transfer of liquids and gases through various plumbing fixtures, including sinks, toilets, and water heaters. By maintaining a secure and airtight bond, pipe joints prevent leaks and ensure the efficient flow of fluids within the system. Depending on the application, there are various types of pipe joints, such as threaded, welded, and glued joints, each designed to meet specific requirements and provide durability under different pressures.

When working with pipe joints, it's crucial to prioritize proper installation to avoid future issues. Here are a few tips to keep in mind: first, always clean and prepare the surfaces of the pipes before joining them, as dirt or debris can lead to imperfect seals. Additionally, ensure the joints are tightened according to the manufacturer's specifications to prevent any movement that might compromise the connection. Regularly checking your plumbing system for any signs of wear or leaks can also help maintain the integrity of your pipe joints.

Furthermore, consider the materials used in your plumbing system. Different types of pipes require specific types of joints, so it's essential to choose compatible materials to ensure longevity and safety. Understanding the various options available can enhance the performance of your plumbing system and prevent costly repairs down the line.

When it comes to plumbing systems, understanding the types of pipe joints is crucial for ensuring a reliable and efficient system. There are several common types of pipe joints, each serving specific functions and applications. The most popular types include solvent-weld joints, threaded joints, and flanged joints. Solvent-weld joints are commonly used with PVC pipes, providing a strong, permanent seal ideal for water transport. Threaded joints, often found in metal piping systems, allow for easy disassembly and repair, making them a favorite for applications requiring flexibility. Flanged joints are utilized where quick assembly and disassembly are necessary, such as in large-scale plumbing systems or industrial settings.

When selecting the type of joint to use, consider the medium flowing through the pipes and the conditions they will be exposed to. For high-pressure applications, flanged joints may be the safest option due to their robust design. For residential plumbing, solvent-weld joints often suffice due to their ease of installation and reliable seal.

**Tips:** Always ensure that the fittings are compatible with the type of pipe you are using. Regularly check for leaks, especially in threaded joints, as they may loosen over time. Lastly, when dealing with solvents or adhesives, follow the manufacturer's instructions to ensure a secure and lasting joint.

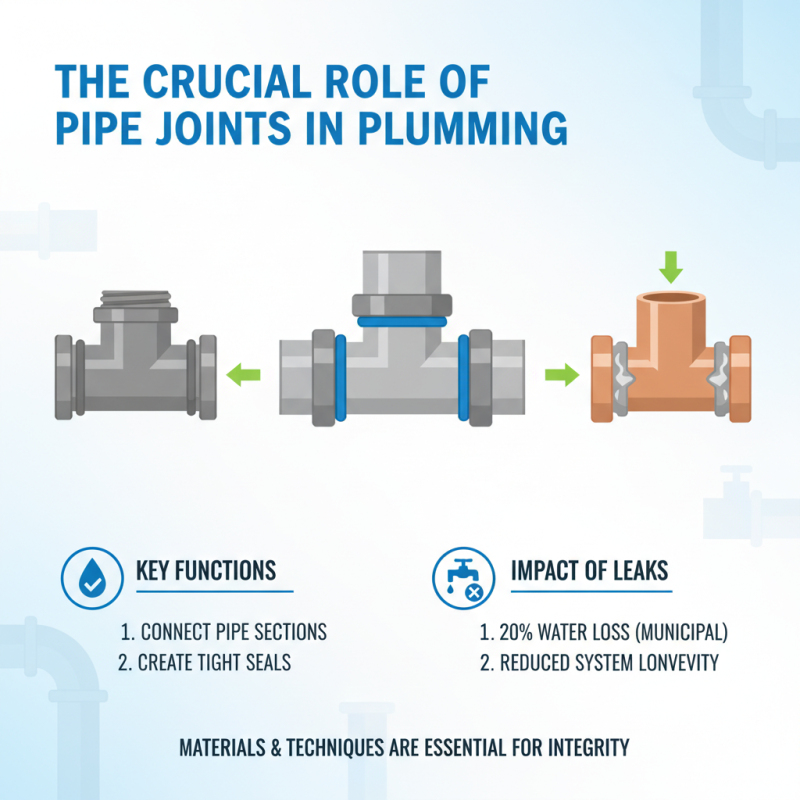

Pipe joints play a crucial role in plumbing systems, serving as the connections between different pipe sections. These joints are designed to create tight seals that prevent the escape of water, gases, or other fluids. According to industry reports, the efficacy of pipe joints can significantly impact the overall performance of plumbing systems, with studies showing that leaks in joints contribute to over 20% of water loss in municipal systems. The materials and techniques used to create these seals are essential for maintaining the integrity and longevity of plumbing installations.

One common method of sealing pipe joints includes the use of gaskets and O-rings, which provide a flexible seal to accommodate movement caused by temperature changes. Furthermore, threaded connections often rely on Teflon tape or pipe dope to enhance their sealing capability. The right selection of joint type—be it welded, flanged, or mechanical—can provide varying degrees of resistance to pressures and environmental conditions, with some joints rated to handle up to 300 psi.

Tips: When installing pipe joints, ensure all surfaces are clean and free of debris to achieve a better seal. Regular maintenance checks are essential for identifying wear or damage in joints early, potentially saving costly repairs down the line. Additionally, using the appropriate sealing materials not only ensures durability but also enhances the efficiency of the entire plumbing system.

When it comes to plumbing systems, the installation of different types of pipe joints is crucial for ensuring integrity and functionality. One of the most common techniques is the use of threaded joints, where male and female threads are cut into the ends of the pipes. This method allows for a secure connection that can withstand high pressures, making it ideal for various applications. It's essential to use appropriate sealing tape or compound on the threads to prevent leaks, ensuring a tight fit and enhancing the longevity of the joint.

Another popular installation technique is the use of soldered joints, commonly found in copper pipe systems. This method requires the application of heat to melt solder at the joint between two pipe ends, creating a strong and durable bond as it cools. Before the soldering process begins, it is vital to clean the surfaces and apply flux to facilitate the flow of solder, ensuring a reliable seal. Proper technique and equipment are critical here, as overheating can lead to damage or weak joints. Understanding these installation methods enables plumbers to select the best approach for each unique situation, ultimately contributing to the overall efficiency of plumbing systems.

| Joint Type | Material | Common Uses | Installation Technique |

|---|---|---|---|

| Compression Joint | Copper, PVC | Water supply lines | Slide in pipe and tighten nut |

| Solder Joint | Copper | Hot water, heating systems | Heat joint and apply solder |

| Threaded Joint | Steel, PVC | Gas lines, irrigation | Twist pipes together with Teflon tape |

| Flanged Joint | Steel, Cast Iron | High-pressure applications | Bolt two flanges together |

| PVC Joint | PVC | Drainage, waste systems | Glue and fit pipes |

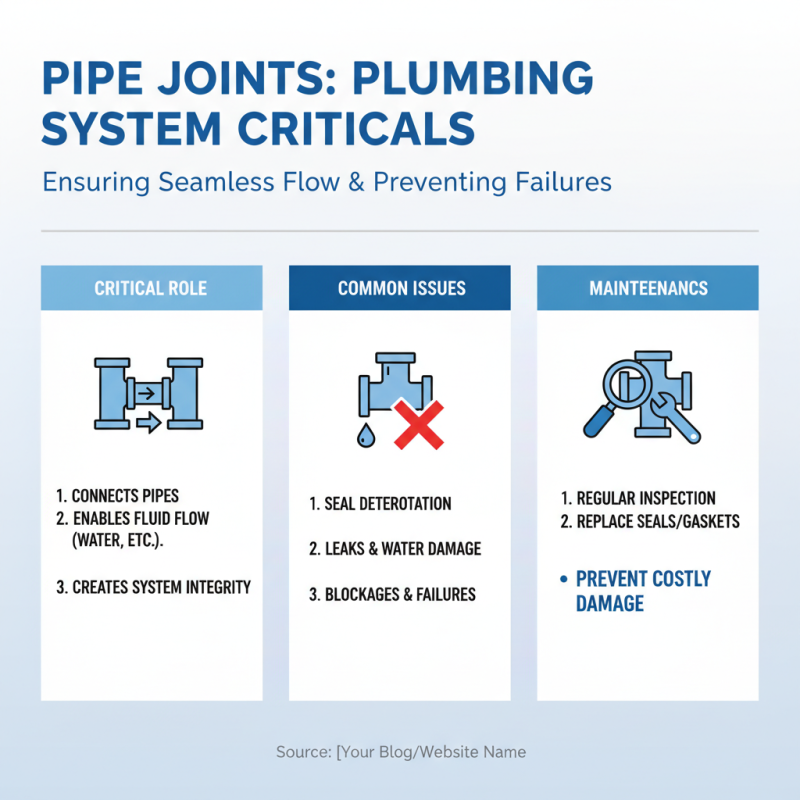

Pipe joints play a critical role in plumbing systems, enabling the connection of various pipes to create a seamless flow of water or other fluids. However, issues can arise in these joints, leading to leaks, blockages, or even complete system failures. One common problem is the deterioration of seals over time, which can allow water to seep out and damage surrounding structures. Regular inspection and maintenance are essential to identify such wear early and replace seals or gaskets as needed to prevent extensive damage.

Another frequent issue is misalignment during installation, which can cause stress on pipe joints and lead to cracks or breakages. Ensuring that pipes are correctly aligned and using appropriate supports can mitigate this risk. Furthermore, corrosion from the internal flow can weaken metal joints, making them prone to leaks. Implementing protective coatings or using corrosion-resistant materials can effectively prolong the life of these joints. By addressing these common problems with proactive solutions, plumbing systems can maintain their integrity and functionality.