Made in America

Get Connected With

Email Us

sale@abrvpartsacc.com

Call Us

+1 (626) 448-2100

Made in America

Get Connected With

In the realm of plumbing, the choice of fittings is crucial for ensuring longevity and reliability in installations. Among various materials, malleable iron fittings have emerged as a preferred option due to their strength and adaptability. According to the American Society of Plumbing Engineers (ASPE), the use of malleable iron fittings can reduce system failures by up to 33% compared to other materials, showcasing their efficiency and durability under pressure.

Industry expert Dr. Michael Henderson, a leading authority on plumbing materials, notes, “Malleable iron fittings not only provide excellent tensile strength but also possess a unique ability to withstand high-temperature fluctuations, making them ideal for diverse plumbing applications.” This statement underlines the essential role that malleable iron fittings play in successful plumbing projects, particularly in environments subjected to varying temperatures and stress.

With improved resistance to corrosion and enhanced adaptability, the demand for malleable iron fittings continues to grow, offering numerous benefits for both residential and commercial plumbing systems. Thus, understanding their advantages can guide plumbers, contractors, and engineers in making informed decisions that ensure the reliability and efficiency of their plumbing solutions.

Malleable iron fittings stand out as a top choice for plumbing due to their impressive strength and durability. These fittings are designed to withstand high pressures and extreme temperatures, making them suitable for a wide range of plumbing applications, from residential to industrial use. Their ability to resist corrosion ensures a longer lifespan and reduced maintenance costs, giving homeowners and plumbing professionals alike peace of mind regarding their installations.

Another significant advantage of malleable iron fittings is their versatility. They can be manufactured into various shapes and sizes, allowing for flexible plumbing designs that meet specific project requirements. Whether it's for water supply lines, drainage systems, or gas piping, these fittings can accommodate different needs seamlessly. Additionally, their ease of installation makes them a favorite among plumbers, further enhancing their appeal in the plumbing industry.

Malleable iron is a versatile material extensively used in plumbing fittings due to its unique composition and properties. Primarily composed of iron with a small percentage of carbon and other alloying elements, malleable iron is crafted through a specific heat treatment process that enhances its ductility and strength. Research indicates that malleable iron can yield a tensile strength ranging between 60,000 to 85,000 psi, making it a robust choice for high-pressure environments typically encountered in plumbing systems.

One of the standout features of malleable iron is its ability to withstand high temperatures and pressures, which is critical for both residential and industrial plumbing applications. According to industry reports, the durability of malleable iron fittings significantly surpasses that of plastic alternatives, which can soften and deform under extreme conditions. This characteristic ensures long-term performance and reliability, particularly in systems that transport hot water or steam.

Tips: When selecting malleable iron fittings for your plumbing projects, consider the specific requirements of your system, including pressure ratings and temperature tolerances. Additionally, ensure proper installation and maintenance to maximize the lifespan of the fittings. Regular inspections can identify potential wear and tear, preventing costly repairs in the future.

When it comes to plumbing materials, durability and longevity are essential considerations that can significantly impact the overall performance and maintenance costs of a system. Malleable iron fittings stand out in this regard due to their remarkable strength and resistance to various forms of wear and degradation. Unlike softer metals or plastic alternatives, malleable iron offers a robust structure that can withstand high pressure and temperature variations, making it a preferred choice in industrial and commercial applications.

Comparatively, materials like PVC or copper may succumb to corrosion or damage over time. PVC, while lightweight and affordable, can become brittle and susceptible to cracking with exposure to heat and UV rays. Copper, although strong, faces issues such as oxidation, which can lead to leaks and decreased functionality. In contrast, malleable iron fittings are coated to prevent rust and can maintain their integrity for decades, even in challenging environments. This durability translates into reduced maintenance frequency and lower replacement costs, ultimately enhancing the reliability of plumbing systems.

| Material Type | Durability (Years) | Corrosion Resistance | Temperature Range (°F) | Weight (lbs/ft) | Cost (per ft) |

|---|---|---|---|---|---|

| Malleable Iron | 50 | Good | -20 to 300 | 7 | $5 |

| PVC | 25 | Excellent | 32 to 140 | 3 | $1.50 |

| Copper | 50 | Good | 0 to 250 | 3.5 | $3.50 |

| Cast Iron | 75 | Fair | -20 to 400 | 10 | $10 |

Malleable iron fittings are becoming increasingly popular in plumbing systems due to their remarkable corrosion resistance. Over time, plumbing materials can succumb to various environmental factors that lead to rust and decay. Malleable iron, however, is designed to withstand these challenges, making it a long-lasting choice for both residential and industrial applications. Its ability to resist corrosion means that pipes and fittings remain durable and dependable, reducing the frequency of repairs and replacements.

When selecting malleable iron for your plumbing needs, consider the environment in which the fittings will be used. In areas with high humidity or exposure to chemicals, ensure that the iron is properly treated or coated to enhance its protective properties. Additionally, maintaining a regular inspection schedule can go a long way in identifying any wear before it develops into a more significant issue.

Tips for optimal use include ensuring that fittings are installed correctly to avoid pressure points that can lead to stress fractures over time. Also, using appropriate linings or sealants can further enhance the corrosion resistance of the system, ensuring that your plumbing remains functional for years to come. Embracing malleable iron fittings not only provides peace of mind but also promotes a more sustainable approach to plumbing.

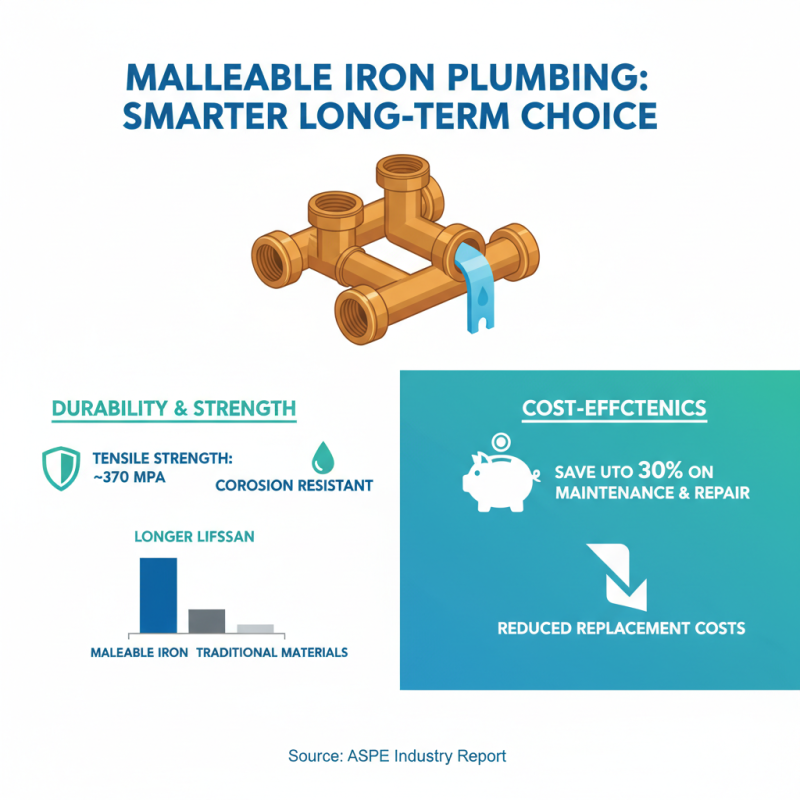

Malleable iron fittings have become a favored choice for plumbing systems, especially when considering long-term cost-effectiveness. According to industry reports, malleable iron demonstrates a tensile strength of approximately 370 MPa, which allows it to withstand high pressures and resist corrosion. This durability translates into a longer lifespan for plumbing systems, providing significant savings on replacement costs over time. A study by the American Society of Plumbing Engineers notes that switching to malleable iron can save up to 30% on maintenance and repair expenses in comparison to traditional materials.

When calculating long-term savings, it is essential to consider installation costs as well. Although the upfront investment for malleable iron fittings can be higher than alternatives such as PVC, the longevity and resilience of iron can lead to a lower total cost of ownership. An analysis reveals that communities using malleable iron have lower overall plumbing repair rates, further contributing to financial savings.

**Tip:** Always ensure that your installation process is done by certified professionals. Proper installation of malleable iron fittings not only enhances their performance but also ensures compliance with local plumbing codes, maximizing their advantages and maintaining system integrity.

Additionally, malleable iron's recyclability adds another layer of cost-effectiveness, making it an environmentally-friendly option. By selecting malleable iron fittings, users can enjoy the benefits of reduced resource consumption and support for sustainable practices in plumbing solutions.

**Tip:** If you're considering different materials for your plumbing system, factor in the entire lifecycle costs, including maintenance, repairs, and environmental impact to make the best decision for your needs.

Malleable iron fittings have emerged as a top choice for plumbing needs due to their unique composition and properties. These fittings offer exceptional durability and longevity when compared to other materials, making them suitable for various applications. Their superior corrosion resistance ensures that they can withstand harsh environments over time, providing reliable performance.

In addition to their durability, malleable iron fittings are cost-effective, as they offer long-term savings through reduced maintenance and replacement needs. Their ease of installation is another significant advantage, allowing for efficient setup in industrial applications. Overall, choosing malleable iron fittings can lead to a more resilient and economical plumbing system.