In today's fast-paced industrial landscape, selecting the right suppliers for high-quality gear pumps is critical for ensuring operational efficiency and enhancing overall productivity. Gear pumps, known for their reliability and capacity to handle various fluids with precision, are integral to numerous applications across industries such as petrochemicals, food and beverage, and pharmaceuticals.

According to a recent market analysis by Grand View Research, the global gear pump market is projected to reach USD 4.91 billion by 2025, growing at a CAGR of 5.2%. This growth underscores the importance of sourcing from suppliers who not only provide superior products but also demonstrate a deep understanding of industry-specific requirements.

Identifying top-quality suppliers hinges on recognizing the specific characteristics and applicability of different gear pump types, tailored to meet the unique demands of your operations.

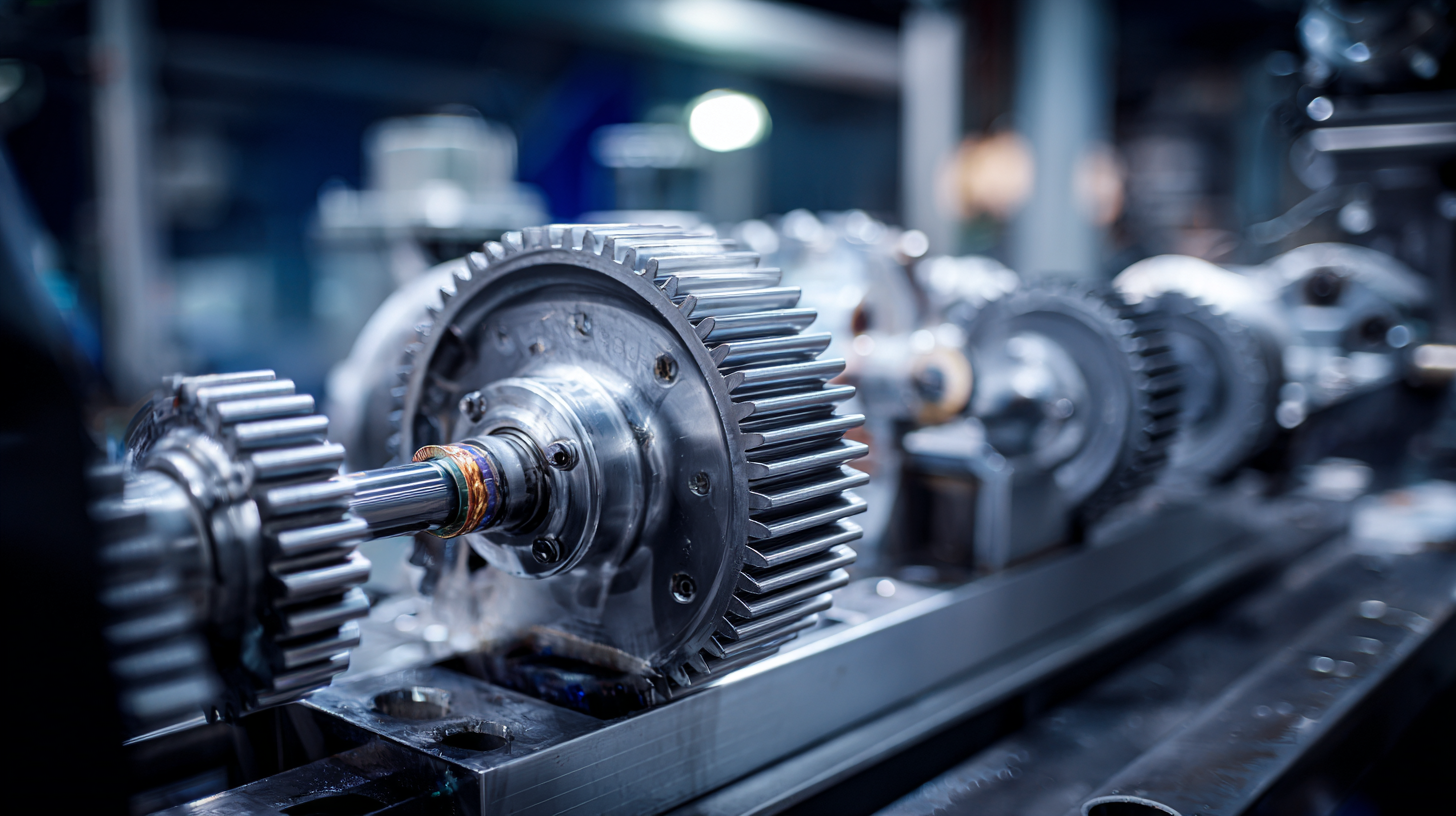

When selecting gear pumps tailored for specific industry applications, it is essential to examine notable case studies that showcase their effectiveness under various operational conditions. For instance, in the oil and gas sector, gear pumps are crucial for transferring viscous fluids. According to a report by MarketsandMarkets, the global gear pump market is projected to reach $3.09 billion by 2025, driven by the growing demand in industries such as petrochemicals and food processing. In these high-demand environments, pumps must withstand extreme conditions, demonstrating reliability and efficiency.

Another compelling application can be found in the automotive industry, where gear pumps play a vital role in lubrication and fluid transfer. A study from Grand View Research indicates that the automotive gear pump segment is expected to witness substantial growth, with a compound annual growth rate (CAGR) of 4.4% from 2020 to 2027. This growth hinges on the continuous innovation in gear pump technology, allowing for enhanced performance, reduced maintenance needs, and improved lifespan—criteria crucial for automotive manufacturers aiming to optimize their production processes. By examining such industry-specific applications, businesses can make informed decisions when identifying top-quality gear pump suppliers that align with their operational requirements and industry standards.

When it comes to sourcing gear pumps, evaluating supplier performance is crucial to ensure you partner with the best in the industry. One effective approach is to analyze industry metrics that assess the supplier's operational efficiency, delivery timelines, and product quality. Metrics such as on-time delivery rates, defect rates, and production capabilities provide a quantitative foundation for your evaluation. By comparing these metrics across potential suppliers, you can better identify those that consistently meet or exceed industry standards.

In addition to hard data, customer reviews serve as invaluable insights into a supplier's reputation and reliability. Positive testimonials can reveal a supplier’s commitment to customer service, responsiveness, and technical support. It's essential to look beyond star ratings; delve into the specific experiences of past clients to understand both strengths and weaknesses. Engaging with a supplier’s existing customers, when possible, can provide a comprehensive view of their performance and help identify any potential red flags. By combining industry metrics with customer feedback, you will be well-equipped to make informed decisions and select top-quality suppliers for your gear pump needs.

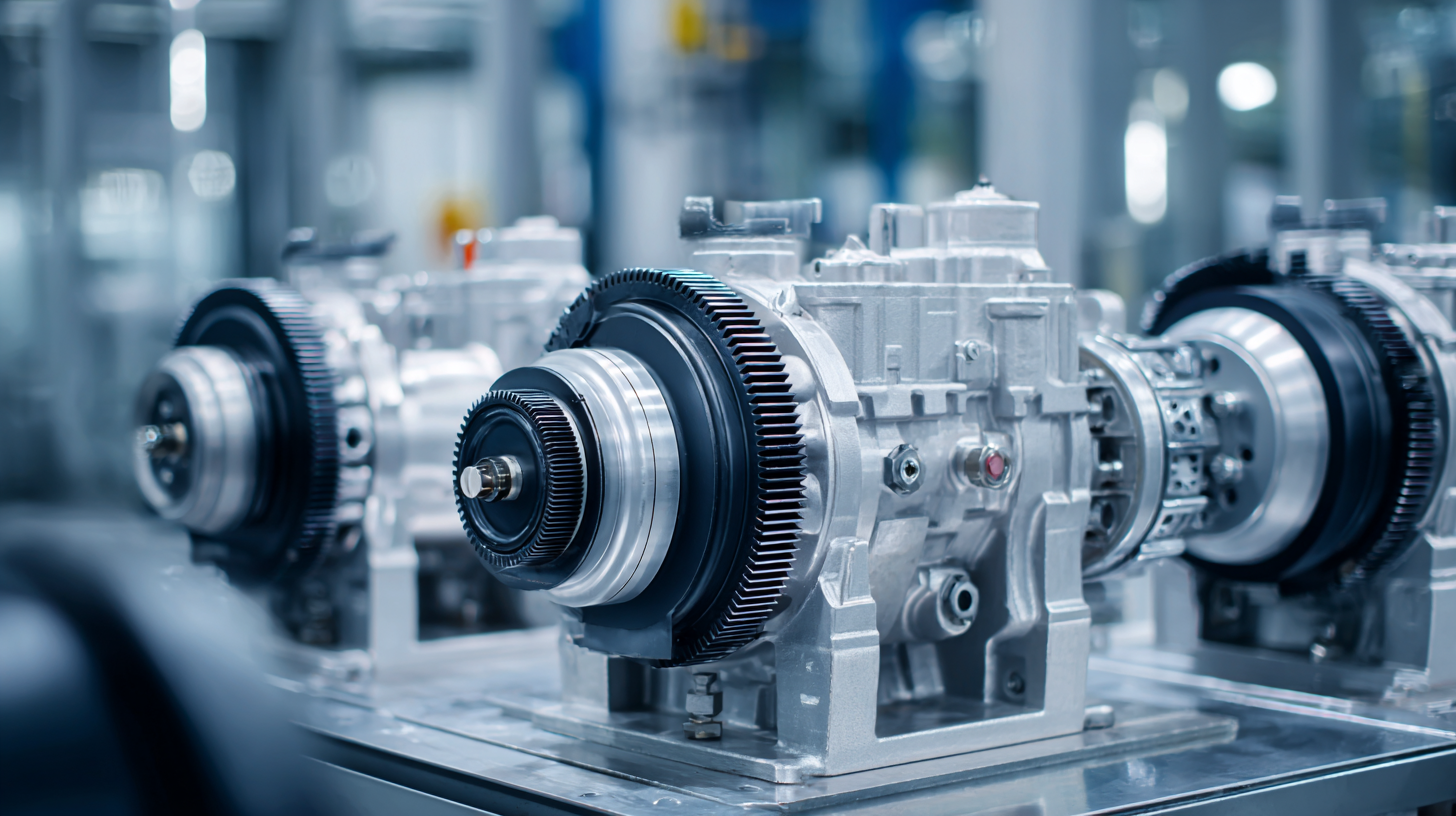

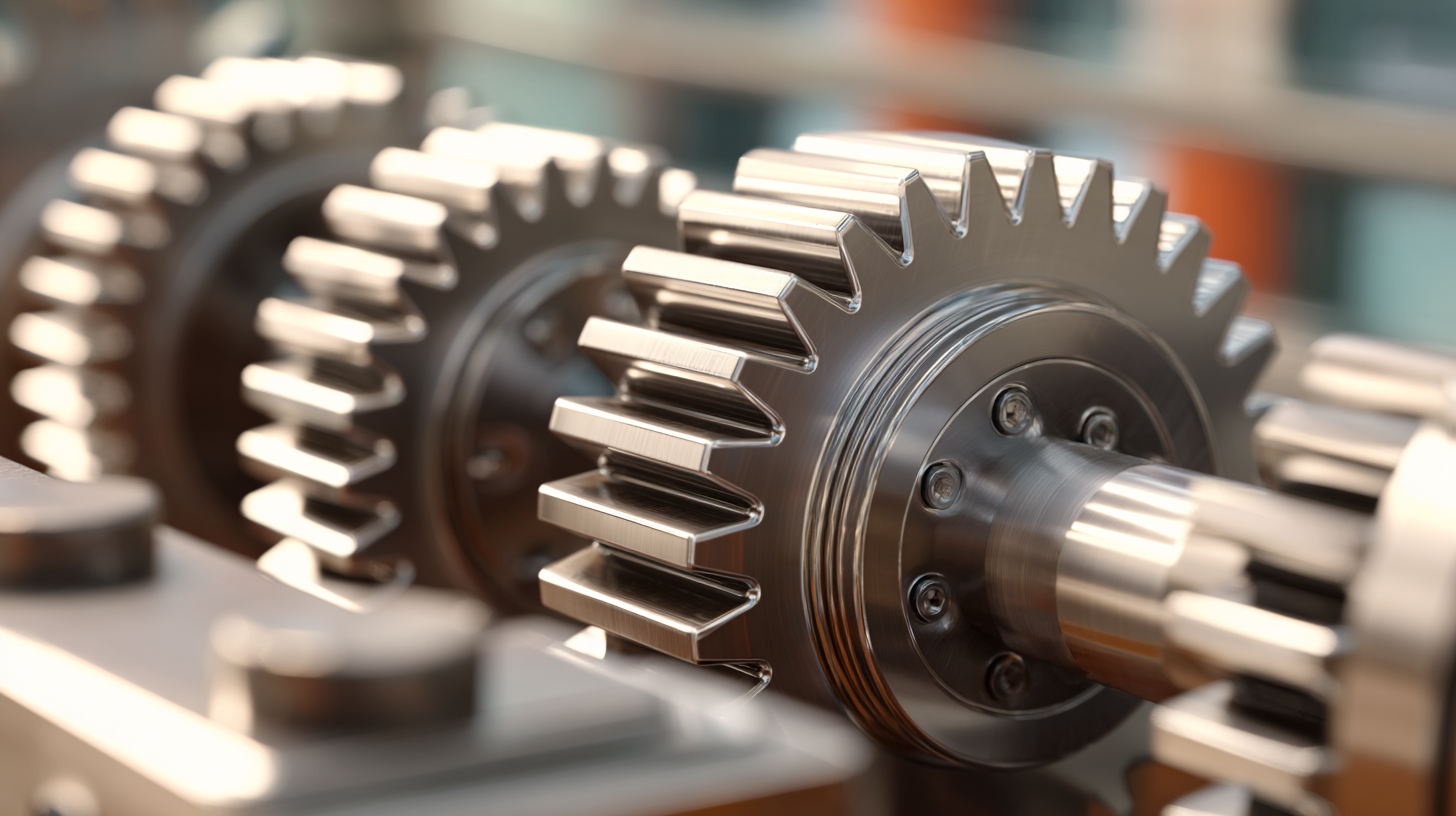

When searching for a top-quality gear pump, understanding its specifications is crucial for ensuring durability and optimal performance tailored to your industry’s needs. Key features to consider include the material of the pump casing. High-quality gear pumps often utilize robust materials like stainless steel or cast iron, which provide excellent resistance to wear and corrosion. It's vital to assess the pump's capacity to handle the fluids being processed, as this directly impacts efficiency and reliability.

Another essential feature is the pump's design, particularly the configuration of the gears. Types such as helical or spur gears can offer different flow characteristics and operational efficiency. Ensure that the gear pump has precise tolerances and fits well to minimize leakage and wear, enhancing longevity. Additionally, consider serviceability aspects, such as ease of maintenance and access to replacement parts, which can significantly affect the pump's total lifecycle cost. By focusing on these specifications, you can identify reliable suppliers that provide equipment designed for excellence and sustained performance in your operations.

When selecting suppliers for gear pumps, understanding the significance of certifications can be a game changer. The International Organization for Standardization (ISO) sets rigorous standards that help ensure product quality and reliability. According to a report from the International Trade Centre, businesses that engage with ISO-certified suppliers witness up to a 20% increase in operational efficiency. This demonstrates that adherence to these standards not only guarantees quality but also enhances overall performance in production lines.

**Tip:** When evaluating suppliers, always request their ISO certifications. This documentation confirms their commitment to maintaining quality management systems throughout their operations.

ISO certifications, particularly ISO 9001, focus on quality management principles that can lead to consistent quality in products. Moreover, suppliers with ISO certifications are often subjected to regular audits, ensuring they continuously meet industry standards. Research from Deloitte indicates that partnerships with ISO-certified suppliers can reduce risk by 30%, providing further incentive to prioritize these certifications in your supplier selection process.

**Tip:** Look for suppliers who display ISO compliance prominently in their marketing materials, as this can be an initial indicator of their commitment to quality.

| Criteria | Importance Level | Certification Standards | Frequency of Audit |

|---|---|---|---|

| Quality Control | High | ISO 9001 | Annual |

| Environmental Management | Medium | ISO 14001 | Every 3 Years |

| Occupational Health and Safety | High | ISO 45001 | Annual |

| Energy Management | Medium | ISO 50001 | Every 3 Years |

| Product Safety | High | ISO 22000 | Biannual |

When searching for the best gear pump suppliers, a critical consideration often arises: how to achieve the perfect balance between cost and quality. While it can be tempting to choose the most affordable option, doing so might lead to compromised performance and increased maintenance costs in the long run.

High-quality gear pumps often come with a higher price tag, but investing in quality can enhance efficiency and durability, ultimately saving you money over time.

To identify top-quality suppliers, it is essential to evaluate their product offerings not just on price, but also on performance metrics, material quality, and customer reviews. Engaging with suppliers who prioritize innovation and robust testing procedures will ensure that you receive equipment that meets the rigorous demands of your industry.

Additionally, consider the total cost of ownership rather than just the upfront price—this includes factors such as lifespan, energy consumption, and potential repair costs. By focusing on both cost and quality, you can make informed decisions that prioritize long-term performance and reliability while staying within budget constraints.