Made in America

Get Connected With

Email Us

sale@abrvpartsacc.com

Call Us

+1 (626) 448-2100

Made in America

Get Connected With

When it comes to plumbing, the importance of choosing the right sewer fittings cannot be overstated. With the potential for significant problems arising from improper installation or selection, understanding the nuances of these essential components is crucial for both professionals and homeowners alike. Renowned plumbing expert John Matthews emphasizes this point, stating, "Selecting the right sewer fittings is not just about convenience; it’s about ensuring the longevity and effectiveness of your plumbing system."

In this ultimate guide, we will explore the various types of sewer fittings available in the market, their applications, and key factors to consider during selection. From bends and tees to couplings and cleanouts, understanding each component's role and functionality helps ensure a seamless plumbing experience. By making informed decisions about sewer fittings, you can mitigate risks, enhance the efficiency of your plumbing system, and ultimately save time and money on repairs.

Join us as we delve into an exhaustive overview of sewer fittings, providing you with essential insights and tips that will empower you to make the best choices for your plumbing needs. With expert guidance and practical advice, you'll be well-equipped to tackle any plumbing project with confidence.

When it comes to plumbing, understanding the various types of sewer fittings is crucial for ensuring a properly functioning drainage system. Sewer fittings serve as connectors, allowing for the seamless transition between different sections of piping. The most common types include elbows, tees, and couplings. Elbows facilitate changes in direction, making them essential for navigating around obstacles in your plumbing layout. Tees, on the other hand, enable junction points where multiple pipes can join, which is often necessary when diverting water flow to different areas. Couplings provide a straightforward way to connect two lengths of pipe, ensuring a tight seal and maintaining the integrity of the sewage system.

Another important category of sewer fittings is traps and cleanouts. Traps are designed to hold a small amount of water, creating a barrier that prevents sewer gases from entering the home while allowing wastewater to exit. Cleanouts are strategically placed fittings that provide access to the sewer line for maintenance and cleaning, a vital feature for preserving the longevity of the plumbing system. Choosing the right fittings based on these functions will help you tailor your plumbing to meet specific needs while enhancing efficiency and durability.

When selecting sewer fittings for plumbing needs, there are several critical factors to consider to ensure optimal performance and durability. Firstly, the material of the fittings plays a pivotal role. Common materials include PVC, ABS, and cast iron, each offering distinct advantages in terms of strength, corrosion resistance, and ease of installation. For instance, PVC fittings are lightweight and resistant to chemicals, making them suitable for residential plumbing, while cast iron fittings provide robust solutions for underground installations due to their durability.

Another important aspect is the pipe diameter and fitting size, which needs to be compatible with the existing plumbing system. Ensuring a proper fit helps prevent leaks and maintains effective drainage. Additionally, consider the type of connection required, whether it be solvent welding or mechanical fastening, as this affects both installation complexity and future maintenance. Lastly, evaluating local codes and regulations regarding sewer systems is essential, as compliance ensures that the plumbing work meets safety and operational standards. By taking these factors into account, homeowners and builders can choose the right sewer fittings that cater to their specific plumbing requirements.

This bar chart illustrates the important factors to consider when selecting sewer fittings for plumbing needs. The factors are rated based on their importance on a scale of 1 to 10.

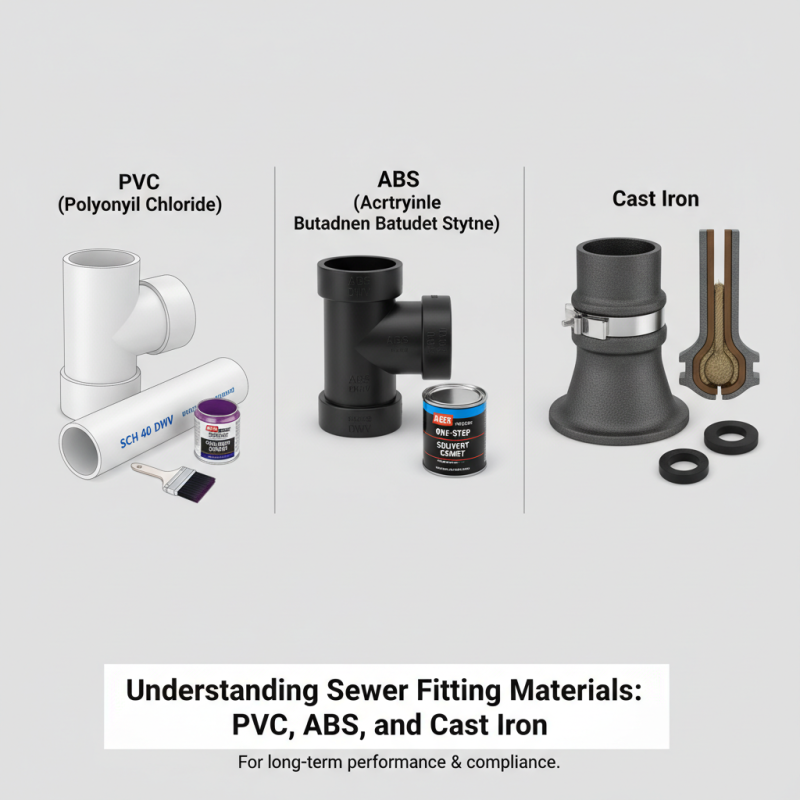

When it comes to selecting the right sewer fittings, understanding the material options is crucial for ensuring long-term performance and compliance with plumbing codes. The three most common materials used for sewer fittings are PVC (Polyvinyl Chloride), ABS (Acrylonitrile Butadiene Styrene), and cast iron. Each material has distinct properties that make it suitable for different applications, significantly influencing installation practices and maintenance requirements.

PVC is widely recognized for its durability and resistance to corrosion. According to the Plastic Pipe and Fittings Association (PPFA), PVC pipes can last over 100 years under normal conditions, making them an economical choice for many plumbing applications. Additionally, PVC is lightweight, which facilitates easier handling and installation compared to heavier materials. However, it is important to note that PVC fittings may not tolerate extreme temperatures and are susceptible to degradation when exposed to certain solvents.

On the other hand, ABS fittings offer advantages in terms of impact resistance and are less likely to crack under pressure. A study published by the American Society of Plumbing Engineers (ASPE) indicates that ABS systems are particularly effective in low-temperature climates due to their higher tolerance for cold. Meanwhile, cast iron fittings, while being the traditional choice for sewer systems, provide excellent sound-dampening qualities and can withstand harsh environmental conditions. The National Association of Home Builders (NAHB) highlights that cast iron is often preferred for commercial plumbing where durability and noise reduction are paramount, although it comes with higher installation costs due to its weight and the need for specialized tools.

When it comes to sewer fittings, proper measurements are crucial for ensuring a reliable and efficient plumbing system. Sizing sewer fittings correctly allows for optimal flow and reduces the risk of blockages. This process involves taking precise measurements of both the pipe diameter and the angles of the connections.

Mismatched sizes can lead to leakage, increased pressure, or even system failure, emphasizing the importance of accuracy before making a purchase.

Moreover, understanding the layout of your plumbing—such as the distance between fixtures and changes in elevation—can significantly impact the selection of sewer fittings. Each fitting plays a specific role in directing wastewater effectively, and the wrong fitting can disrupt this delicate balance. Taking time to measure and calculate will not only enhance the system's performance but also save on future repairs and maintenance costs, making it essential for any plumbing project, whether residential or commercial.

When installing sewer fittings, one of the most common mistakes is improper alignment.

Fittings that are not aligned correctly can lead to leaks,

blockages, and long-term damage to plumbing systems.

To avoid this issue, it's critical to ensure that all pipes and fittings are aligned perfectly before securing them.

Using a level can help verify that each piece is positioned correctly, preventing future complications and costly repairs.

Another frequent error is neglecting the importance of proper sealing.

Many DIY installers underestimate the role of gaskets, sealants, or adhesives in creating a watertight connection.

To prevent leaks, it’s essential to apply the appropriate materials as per the specifications of the fittings used.

Taking the time to clean the surfaces and apply seals correctly will significantly enhance the durability of the installation

and minimize the risk of water damage over time.