Made in America

Get Connected With

Email Us

sale@abrvpartsacc.com

Call Us

+1 (626) 448-2100

Made in America

Get Connected With

In 2025, the urgency to address sewer pipe connections has become paramount for both urban planners and homeowners alike. According to the latest report by the American Society of Civil Engineers, an estimated 30% of sewer systems in the United States are in need of urgent repair or replacement, leading to increased risks of blockages and environmental hazards. Fixing sewer pipe connections efficiently can not only save substantial costs associated with emergency repairs but also enhance community health standards. As industry expert Dr. James Ellison states, “Understanding the intricacies of sewer pipe connections is crucial in preventing future degradation and ensuring sustainability in our infrastructure systems.”

Moreover, advancements in technology and methods for repairing sewer pipe connections have evolved significantly over recent years. Innovative solutions, such as trenchless technology, have reduced the cost and disruption associated with traditional methods of repair. A report from the National Association of Sewer Service Companies reveals that these modern approaches can decrease repair times by up to 70%, allowing for more efficient recovery of sewer systems. Therefore, focusing on effective strategies in 2025 to address sewer pipe connections can provide a holistic solution, safeguarding both public health and financial resources.

Sewer pipe connection issues are a common concern for homeowners and professionals alike, particularly as systems age and materials degrade over time. In 2025, understanding these challenges is crucial for effective maintenance and timely repairs. One prevalent problem is the misalignment of pipe sections, which can occur due to ground shifting or inadequate installation. This misalignment can lead to blockages and leaks, significantly impacting the overall functionality of the sewer system.

Another frequent issue involves the deterioration of sealing materials. Pipes are often joined using various types of adhesives and sealants, which can lose their effectiveness over the years. In 2025, it is essential to recognize when these materials have weakened and require replacement to prevent infiltration and ensure a watertight seal. Additionally, root intrusion is a major challenge for sewer connections, especially in areas with large trees. Roots can penetrate joints, causing clogs and damage to the pipe structure. Addressing these common sewer pipe connection problems effectively requires both knowledge and attention to detail, ensuring a longer lifespan for the sewer system.

| Issue | Common Causes | Symptoms | Quick Fixes | Long-term Solutions |

|---|---|---|---|---|

| Leaky Connections | Loose fittings, corrosion | Water pooling, foul odor | Tighten fittings, use plumber's tape | Replace old fittings, regular inspections |

| Blocked Connections | Debris buildup, tree roots | Slow drainage, gurgling sounds | Use a drain snake, hot water flush | Routine cleaning, root barriers |

| Misaligned Pipes | Ground shifts, poor installation | Backflow, leaks at joints | Adjust pipes, seal joints | Professional realignment, support systems |

| Cracked Pipes | Age, extreme temperatures | Leaks, soil erosion | Epoxy sealant, temporary patching | Pipe replacement, insulation |

| Inadequate Venting | Improper installation, blockages | Foul odors, slow drainage | Clear vents, add supplemental venting | Review and upgrade system as needed |

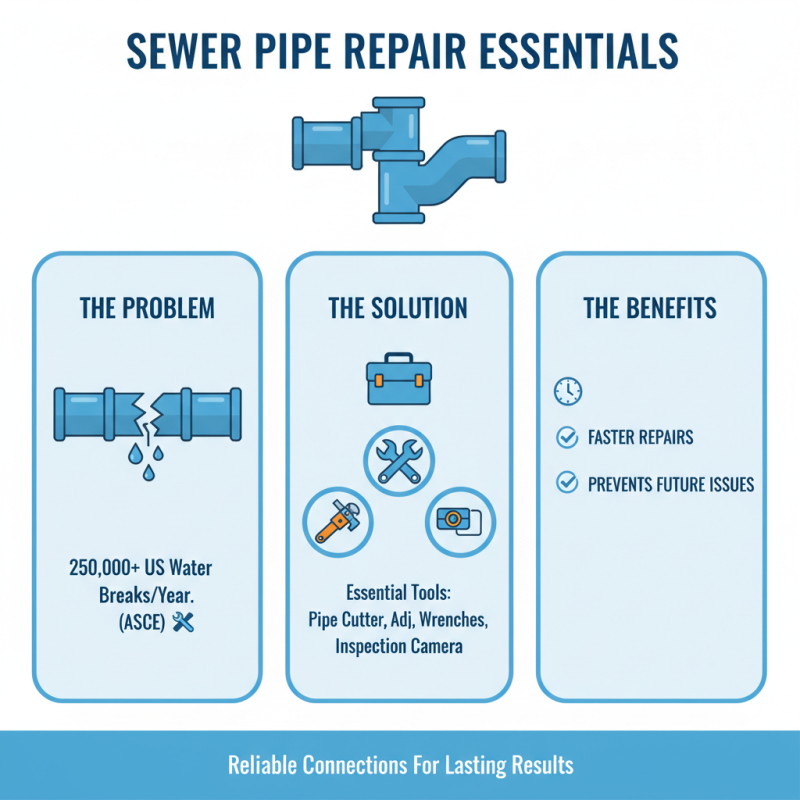

When tackling sewer pipe connection repairs, having the right tools and materials is essential for effective and lasting results. According to the American Society of Civil Engineers, an estimated 250,000 water main breaks occur in the United States each year, highlighting the critical nature of maintaining reliable pipe connections. To ensure successful repairs, homeowners and professionals alike should have a well-stocked toolkit that includes essential items such as a pipe cutter, adjustable wrenches, and a pipe inspection camera. The use of these tools not only speeds up the repair process but also increases the likelihood of identifying existing problems that could lead to future issues.

In addition to the tools, selecting the appropriate materials is just as vital. The National Association of Plumbing and Heating Contractors reports that the choice of pipe materials, such as PVC, ABS, or cast iron, can significantly impact the longevity of repairs. For instance, PVC is often recommended for its lightweight nature and resistance to corrosion, making it ideal for residential sewer systems. Likewise, pipe joints should be fitted with high-quality sealants and connectors that can withstand fluctuating environmental conditions. Implementing these best practices will enhance the effectiveness of sewer pipe connection repairs and contribute to better overall infrastructure.

When dealing with leaky sewer pipe connections, it's essential to follow a systematic approach to ensure an effective repair. First, identify the source of the leak by visually inspecting the connections and surrounding areas for signs of water damage or dampness. Carefully clean the affected area to remove any debris, rust, or old sealant, which may hinder the repair process. Use a suitable pipe cleaner or brush to prepare the surfaces of the pipes and fittings, making sure they are dry before proceeding.

Next, select the appropriate repair materials for your specific pipe type, whether it's PVC, cast iron, or another material. Apply the chosen sealant or adhesive according to the manufacturer's instructions, ensuring an even application around the connection. If you're using a mechanical repair method, such as a coupling, firmly secure it to ensure a tight seal. After the repair is complete, it’s important to allow adequate drying time before testing the connection with water. This step is crucial to confirm that the leak is fully sealed and that your sewer system is operating effectively once again.

Testing and verifying the integrity of repaired sewer pipe connections is crucial to ensure effective long-term performance and prevent future issues. One effective method is using a pressure testing system, which involves sealing the repaired area and introducing air or water to check for leaks. This method not only identifies immediate failures but also assesses the overall strength of the connection. A drop in pressure or the appearance of bubbles indicates a compromised seal that requires further attention.

In addition to pressure testing, visual inspections conducted with the help of cameras can provide clear insights into the internal condition of the pipe connections. By using specialized equipment, professionals can detect misalignments, cracks, or root intrusions that may not be visible from the surface. This approach allows for a comprehensive evaluation of the integrity of the repairs and informs necessary adjustments or additional repairs, ensuring the entire sewer system operates efficiently. Regular monitoring and testing post-repair are essential to maintaining system integrity over time, allowing for proactive maintenance measures.

Maintaining healthy sewer pipe connections is essential for ensuring a smoothly functioning plumbing system and preventing costly repairs. According to the American Society of Civil Engineers, 20% of wastewater facilities are at risk of failure due to aging infrastructure. Regular inspections and preventive maintenance can drastically reduce these risks. Utilizing advanced technology, such as CCTV inspections, homeowners can spot issues early on, addressing small problems before they escalate into more serious complications.

Tips for maintaining your sewer pipe connections include regularly cleaning your pipes to avoid blockages caused by buildup, which accounts for approximately 40% of sewer backups. Installing strainers and filters can also effectively catch debris and prevent it from entering the drainage system. Furthermore, being mindful of what goes down the drain can save significant headaches; grease, food scraps, and non-biodegradable items should always be disposed of properly to maintain a healthy sewer system.

Another preventive measure is to ensure that all connections are properly sealed. According to the Environmental Protection Agency, leaks from sewer pipes can lead to groundwater contamination. Regularly checking for visible leaks or signs of moisture around connections can help identify issues early. Additionally, using flexible, durable materials for connections can provide greater resilience against shifts in soil and temperature, ensuring your sewer system remains in good working order.