Made in America

Get Connected With

Email Us

sale@abrvpartsacc.com

Call Us

+1 (626) 448-2100

Made in America

Get Connected With

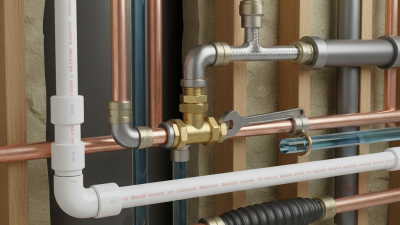

When selecting pipe joints for a project, many factors demand attention. Industry expert James Thompson emphasizes, "The right pipe joints can make or break your system." This notion resonates deeply in construction and plumbing projects where reliability is paramount.

Choosing the appropriate pipe joints involves understanding their materials, sizes, and applications. Each decision influences the overall performance of piping systems. A common mistake is overlooking the specific requirements of the project. For instance, not considering the environment may lead to premature failures.

Pipe joints are not merely connectors; they are critical components that dictate efficiency. Flawed choices can result in leaks and costly repairs. Hence, knowing how to assess and select quality pipe joints is essential for success. Missteps in this area can disrupt project timelines and budgets, underscoring the need for careful consideration and expert guidance.

When selecting pipe joints, understanding the different types available is crucial. There are various types of joints, each suitable for specific applications. Welded joints are strong but require skills. Threaded joints are easy to install but can leak if not properly tightened. Flanged joints allow for easy assembly and disassembly, making them ideal for maintenance. According to industry reports, approximately 30% of plumbing failures are due to joint failures. This emphasizes the importance of choosing the right joint.

Tip: Always consider the working pressure and temperature. Ensure the joint's specifications align with your project's requirements. Chinese data indicates that improper joint selection can affect system efficiency by up to 25%. Choosing the wrong joint might lead to costly repairs.

Another type, compression joints, offers a simple install method and is versatile. However, they may not hold up under heavy stress. Look for joints made from durable materials like stainless steel or brass. These materials can withstand increased pressure and reduce the risk of failure. Remember that not all pipe joints are created equal. Some may look good but may not perform well in practice.

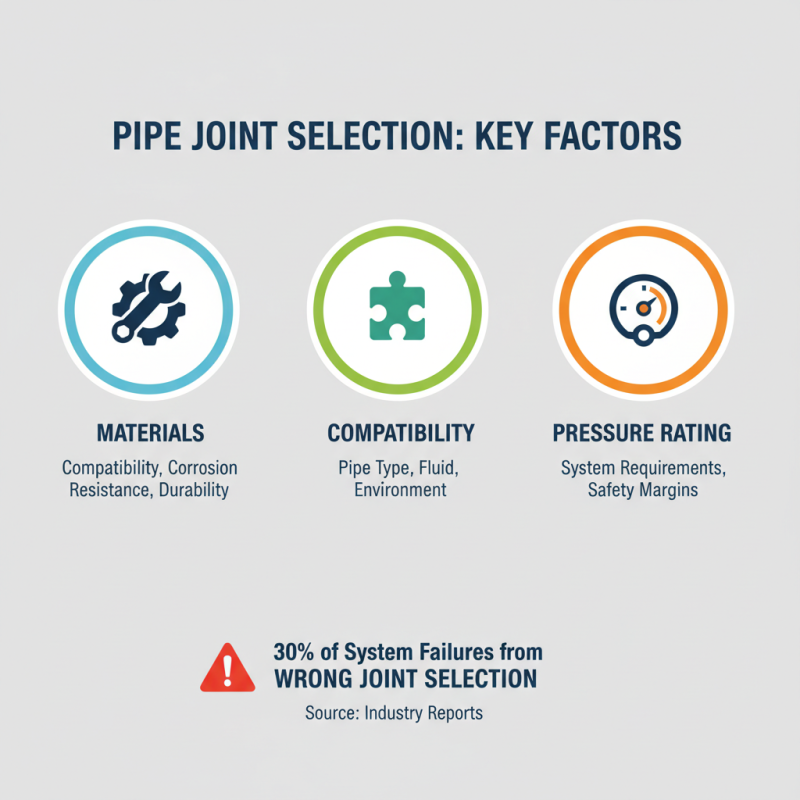

When selecting pipe joints for your project, several key factors demand attention. Not all pipe joints are created equal; materials, compatibility, and pressure ratings significantly influence performance. According to industry reports, approximately 30% of system failures are attributed to improper joint selections. This emphasizes the need for thorough evaluation.

Compatibility with existing systems is critical. For instance, metal joints should not be used with certain plastics, as chemical reactions may occur. Understanding the specifications of your project helps in choosing suitable materials. Reports indicate that using the right joint can enhance durability by up to 25%.

Pressure ratings must also align with project requirements. If a joint cannot withstand the pressure, leaks and failures are likely. Industry experts suggest reviewing technical data and consulting professionals to avoid costly mistakes. Gathering information can be tedious, but it's essential for success. Ignoring these factors often leads to regrets down the line.

When selecting pipe joints, material choice is crucial. Different materials come with distinct benefits and drawbacks.

Metal joints are known for their durability and strength. They resist high temperatures and pressures well. However, metal can corrode over time, especially in wet environments. This can lead to costly repairs and replacements.

On the other hand, plastic joints offer excellent resistance to corrosion and chemicals. They are lightweight and easy to install. However, plastic may not withstand extreme temperatures as effectively. In cold weather, some plastic types can become brittle. Using the wrong type can result in failures or leaks.

Consider your project's specific conditions. The environment will dictate the longevity of your chosen pipe joint material. Evaluate your needs carefully. Sometimes, a combination of materials may be the answer. There’s no one-size-fits-all solution. Explore your options and weigh them against your budget and project requirements.

Choosing the right pipe joints for your project requires careful consideration. Start by evaluating joint sizes carefully. It’s crucial that the joints fit the pipes securely. Measure the diameter and length of your pipes accurately. An improper size can lead to leaks or weaknesses.

Next, consider compatibility with different pipe systems. Some joints may work well with specific materials but fail with others. PVC, copper, and steel all have unique requirements. A joint suitable for PVC might not hold up for steel. Be mindful of this while selecting your joints.

Don't underestimate the importance of joint type. Some joints are better for specific functions, like high pressure or temperature. In some cases, you may also find issues with joint alignment. Inadequate alignment can weaken the entire system. Keep these factors in mind to avoid costly mistakes. Testing the joints after installation is essential, too. Even slight imperfections can lead to significant problems later.

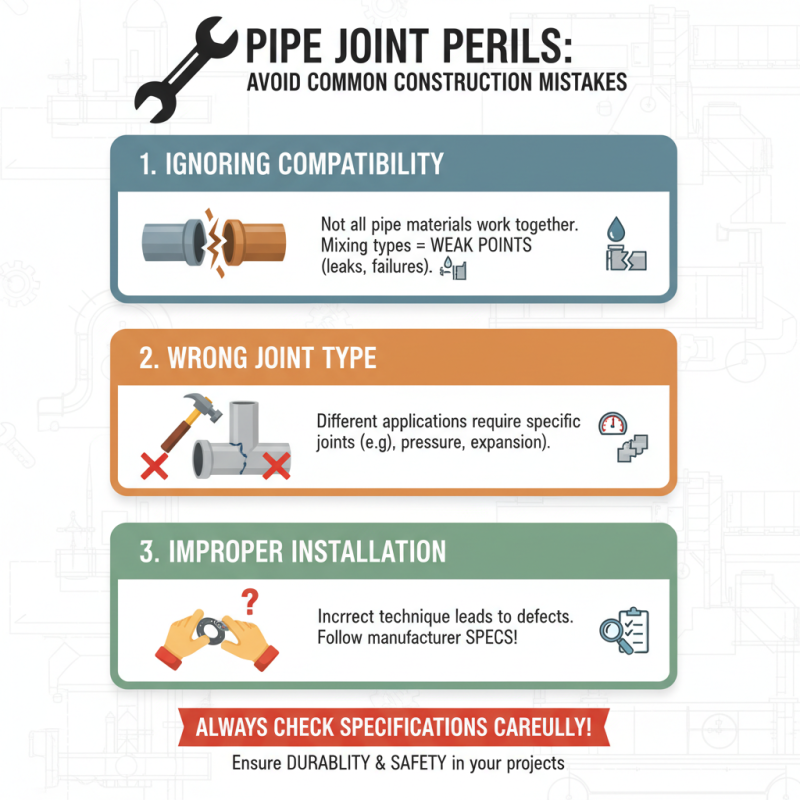

Choosing the right pipe joints for construction projects can be tricky. Many make avoidable mistakes that lead to issues down the line. One common error is ignoring compatibility. Not all pipe materials work well together. Mixing different types can create weak points, leading to leaks or failures. Always check specifications carefully.

Another mistake is underestimating the environmental factors. Temperature changes and humidity can affect joint performance. If you're in a high-pressure area, using standard joints may not suffice. It’s critical to consider the project's specific conditions. A joint suitable for indoors might not hold up outdoors.

Lastly, rushing the selection process can have lasting consequences. Take time to assess your needs. Seek input from experienced colleagues or professionals. It’s worth investing extra effort into selecting the right joints. Proper research today prevents costly repairs later. Many have faced issues simply for overlooking these steps.