Made in America

Get Connected With

Email Us

sale@abrvpartsacc.com

Call Us

+1 (626) 448-2100

Made in America

Get Connected With

The role of pipe manufacturing in modern infrastructure development is a cornerstone of economic growth and urbanization. As cities expand and technologies evolve, the demand for reliable and durable piping solutions becomes increasingly critical. According to Dr. Emily Thompson, a leading expert in the field of civil engineering, "The future of urban infrastructure relies heavily on the advancements we make in pipe manufacturing; without it, our cities cannot sustain the populations they are expected to support."

Pipe manufacturing not only provides essential materials for water supply, sewage systems, and gas distribution but also fosters innovation that drives efficiency and sustainability in construction practices. The demand for high-quality pipes has surged, reflecting the urgent need for resilient infrastructure systems capable of withstanding environmental challenges and meeting the growing needs of urban populations. As we explore the intricate relationship between pipe manufacturing and infrastructure development, it becomes evident that this sector is fundamental to building a sustainable future.

In this context, the significance of pipe manufacturing extends beyond mere fabrication; it encompasses the responsibility to develop systems that enhance the quality of life in our communities. The innovations derived from this vital industry pave the way for smarter cities and more efficient resource management, ultimately shaping the landscape of modern infrastructure.

Pipes are indispensable components of modern infrastructure systems, playing a critical role in various applications ranging from water supply and sewage systems to heating and cooling networks. Their primary function is to facilitate the transport of fluids and gases over distances while ensuring safety and efficiency in delivery. This transport capability is vital for urban development, where a reliable water supply is necessary for both residential and commercial needs. In addition to water, pipes are essential for waste management, aiding in the efficient removal of sewage and preventing environmental contamination.

Moreover, the role of pipes extends beyond just fluid transport; they are integral to the functionality of various infrastructure systems including energy, communications, and transportation. For instance, pipelines are used to distribute natural gas for heating and cooking, while fiber optic cables—often housed within protective piping—enable high-speed internet connectivity. The strength and durability of the materials used in pipe manufacturing ensure that these systems can withstand environmental challenges, such as fluctuating temperatures and pressure. In summary, pipes are foundational elements in facilitating the seamless operation of infrastructure, which is crucial for the development and sustainability of modern societies.

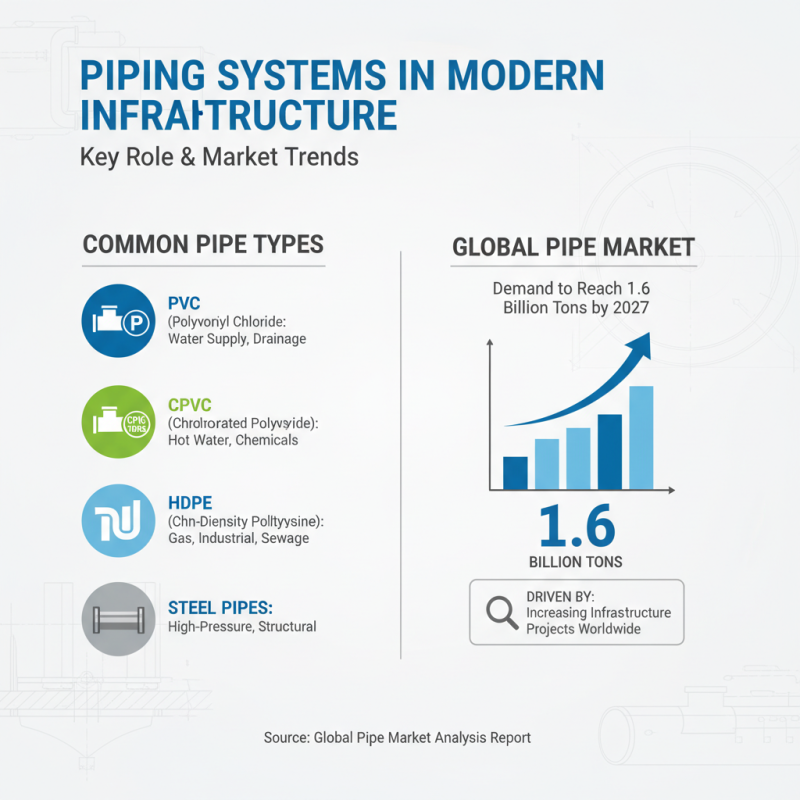

Piping systems play a crucial role in modern infrastructure development, serving various applications from water supply to drainage systems. The most commonly used pipes in construction include PVC (Polyvinyl Chloride), CPVC (Chlorinated Polyvinyl Chloride), HDPE (High-Density Polyethylene), and steel pipes. According to a report by the Global Pipe Market Analysis, the overall demand for pipes is expected to reach 1.6 billion tons by 2027, driven by increasing infrastructure projects worldwide.

PVC pipes are widely used for potable water distribution and irrigation systems due to their corrosion resistance and lightweight properties. They offer a significant advantage in installation costs and have a long service life, often exceeding 50 years. On the other hand, HDPE pipes are favored for their high strength-to-density ratio, making them suitable for underground utilities and gas distribution. With the growing emphasis on sustainable practices, industries are also leaning towards materials that have a lower environmental impact. This shift is reflected in the expected growth of the green pipe market, projected to expand at a CAGR of 6.5% until 2025.

Steel pipes, while heavier, provide durability and strength, making them ideal for high-pressure applications such as oil and gas transmission. They are also resistant to extreme temperatures, which is critical for certain infrastructure projects. As reported by the American Society of Civil Engineers, a significant portion of the nation's existing pipelines is reaching the end of its lifecycle, underscoring the urgent need for modern pipe manufacturing techniques that can meet contemporary demands for safety and efficiency.

The manufacturing of pipes plays a pivotal role in modern infrastructure development, relying on several key processes to ensure the delivery of high-quality products. One of the essential steps in pipe manufacturing is extrusion, where raw materials are heated and forced through a mold to create long, continuous shapes. This method is particularly effective for producing thermoplastics, allowing for precise control over dimensions and improved surface finishes. By varying temperature and speed, manufacturers can customize the pipe’s properties, ensuring they meet specific performance criteria for various applications, from water supply systems to gas transportation.

Another critical process is welding, essential for joining pipe sections to create continuous lengths for large projects. Techniques such as longitudinal and spiral welding are employed, depending on the design and usage of the pipes. Quality control during this process is crucial, as any weakness in the weld could lead to structural failures. Additionally, manufacturers use non-destructive testing methods, such as ultrasonic or X-ray inspection, to verify the integrity of the welded joints. These processes help achieve reliable and durable pipes that can withstand the pressures and stresses encountered in modern infrastructure setups, reflecting the importance of meticulous manufacturing techniques in this sector.

| Pipe Type | Material | Manufacturing Process | Applications | Quality Standards |

|---|---|---|---|---|

| PVC Pipe | Polyvinyl Chloride | Extrusion | Drainage, Plumbing | ASTM D1784 |

| Steel Pipe | Steel | Seamless/Welded | Oil & Gas, Construction | ASTM A53 |

| HDPE Pipe | High-Density Polyethylene | Extrusion | Water Supply, Sewage | ASTM D3035 |

| Copper Pipe | Copper | Drawn | Plumbing, HVAC | ASTM B88 |

| Concrete Pipe | Concrete | Centrifugal Casting | Stormwater Management | ASTM C76 |

The impact of pipe manufacturing on sustainable development is profound, as it plays a critical role in enhancing resource efficiency and minimizing environmental footprints. According to the Global Pipes Market Report, the demand for pipes is projected to grow at a CAGR of 5.4% from 2022 to 2027, largely driven by urbanization and the need for reliable water management systems. These infrastructure developments are essential for creating efficient waste management, transportation, and water supply systems, which are fundamental components of sustainable urban planning.

Moreover, advancements in pipe manufacturing technologies, such as the use of environmentally friendly materials and processes, contribute to reducing greenhouse gas emissions. The International Energy Agency indicates that the construction and operation of pipelines account for approximately 9% of global energy-related emissions. However, through innovative manufacturing techniques, such as the implementation of recycled materials and energy-efficient production methods, the pipe manufacturing industry is taking significant steps towards reducing its ecological impact. The transition to sustainable practices not only aligns with global environmental goals but also supports the circular economy by promoting the reuse and recycling of materials, reinforcing the importance of this sector in fostering sustainable development.

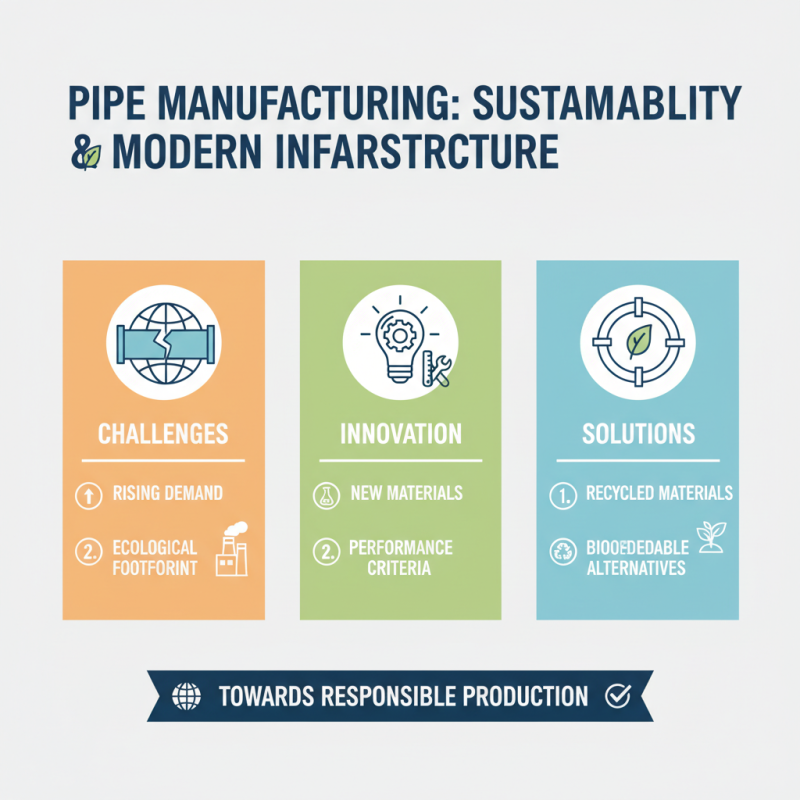

The pipe manufacturing industry faces several challenges that directly impact modern infrastructure development. One of the primary issues is the rising demand for sustainable and environmentally friendly materials. As cities grow and infrastructure expands, manufacturers must innovate by developing pipes that not only meet stringent performance criteria but also minimize their ecological footprint. This has led to the increased use of recycled materials and the synthesis of biodegradable alternatives, representing a significant shift towards more responsible production practices.

In addition to sustainability, advancements in technology play a crucial role in addressing challenges in pipe manufacturing. Automation and smart manufacturing techniques have revolutionized the production process, enhancing efficiency and reducing waste. Moreover, the integration of digital tools such as 3D modeling and predictive analytics helps manufacturers optimize their designs and anticipate maintenance needs. These innovations not only streamline operations but also improve the durability and performance of pipes, ensuring they can withstand the demands of modern infrastructure. Thus, as the industry navigates these challenges, it continues to find creative solutions that enhance the resilience and sustainability of the infrastructures they support.