Made in America

Get Connected With

Email Us

sale@abrvpartsacc.com

Call Us

+1 (626) 448-2100

Made in America

Get Connected With

In the world of crafting and design, mastering custom pipe projects can elevate your creations. These projects often present challenges. Understanding the nuances of custom pipe can lead to impressive results. With the right tips, your outcomes can improve significantly.

Consider the material and tools needed for custom pipe projects. Different materials may require different techniques. Experimentation is key, yet one must be mindful of mistakes along the way. Reflect on your progress. Not every attempt will yield perfection, and that's okay. Each failure teaches valuable lessons.

Exploring these ten tips can help refine your custom pipe skills. These strategies aim to enhance creativity and functionality. Remember, the path to expertise involves trial and error. Embrace the journey while creating something unique and functional. Your projects deserve the best effort.

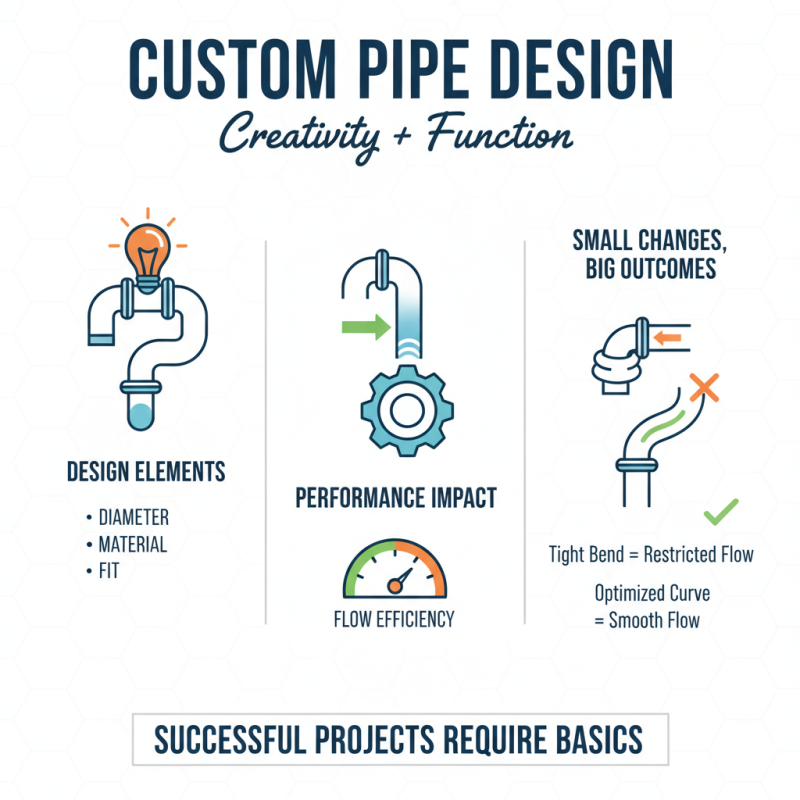

Custom pipe design combines creativity and function. Understanding the basics is essential for successful projects. Each design element affects performance. The right diameter, material, and fit can make a significant difference. Small changes can lead to unexpected outcomes. For example, a too-tight bend may restrict flow.

Start with a clear concept. Sketch your designs and visualize the outcome. Consider the project’s specific needs. Are aesthetics as important as utility? Choosing the wrong material can lead to failure. Reflect on past projects where materials didn't meet expectations. Each mistake offers a learning opportunity.

Experimentation is key. Test variations of your design. You may discover that some elements work better than others. Sometimes, the simplest solutions become the most effective. It’s okay if things don’t go as planned. Adjustments and iterations are part of the process. Embrace the imperfections, as they often lead to growth in your craft.

When diving into custom pipe projects, the right tools are essential. A sturdy workbench can make a huge difference. It provides a stable surface for cutting and assembling. Safety glasses are also crucial. They protect your eyes from debris while you work.

One important tip is to measure twice, cut once. Mistakes can be costly and time-consuming. Use a reliable tape measure to ensure accuracy. A good pipe cutter will help achieve clean edges. Sharp tools are safer and make the job easier. Don't forget to clean your workspace after each project. A tidy area promotes better focus.

There’s no need to rush through a project. Take your time with each step. If something isn’t fitting right, step back and reassess. It’s okay to make mistakes as they often lead to learning. Keep a journal of your ideas and challenges. This reflection can spark new inspiration for your next endeavor.

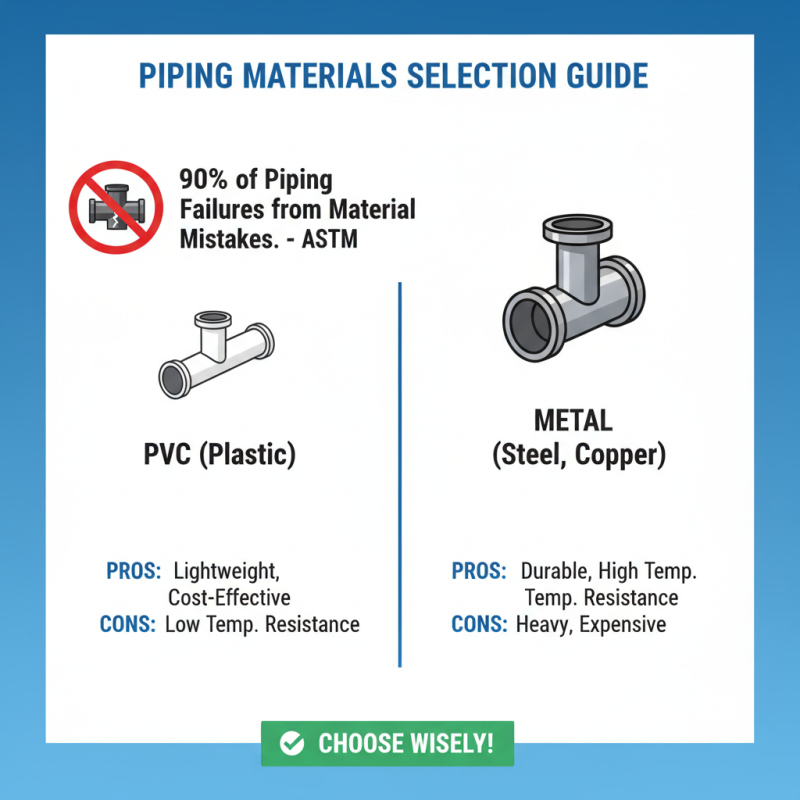

When selecting the right materials for your piping projects, the choices can often feel overwhelming. According to the American Society for Testing and Materials (ASTM), over 90% of piping failures are due to material selection mistakes. This emphasizes the need for careful consideration of the materials you choose. For example, PVC is lightweight and cost-effective, but it may not withstand extreme temperatures. Conversely, metal pipes offer durability but can be heavier and more expensive.

It's essential to assess the specific requirements of your project. Consider the environment where the pipes will be installed. If the pipes are exposed to chemicals or high-pressure systems, using reinforced materials is advisable. A recent report showed that 70% of engineers have encountered issues due to inappropriate material use in their projects. This highlights the importance of rigorous analysis during material selection. Testing samples beforehand can help identify potential weaknesses before the installation phase.

Don't overlook the impact of installation techniques on longevity. Poor installation can overshadow the benefits of even the best materials. Engineers often report that complications during installation have led to up to 30% of project delays. It’s crucial to train your team adequately and ensure meticulous planning. Each step matters—choosing the right materials and proper approaches can elevate the success of your piping projects.

Achieving precision in pipe shaping is crucial for any project. One effective technique is using a caliper to measure your work accurately. A good measurement will save time and resources. It’s essential to check twice before cutting. Remember, even slight mistakes can lead to unsatisfactory results.

Another important aspect is the angle of cuts. Ensure that each angle is precisely cut. A small deviation can throw off the entire structure. Use a miter box for consistent angles, but keep in mind that it may not always align perfectly. Don’t be afraid to take a moment and reassess before moving on.

Practice makes perfect, but it also leads to occasional missteps. You might find that specific techniques don’t work on certain materials. Experimentation is key. Record what works and what doesn’t, so you can refine your approach in future projects. A continuous learning mindset will elevate your skills.

Finishing touches in any project are crucial. According to a recent industry report, nearly 75% of projects fail to meet aesthetic standards due to lack of attention to detail. When it comes to custom pipe projects, quality is paramount. Imperfections can ruin the overall look. Ensuring a smooth finish and even surfaces helps achieve a polished appearance.

Many creators overlook the significance of aesthetics. Factors such as color consistency and alignment can detract from the final result. For instance, uneven paint application on pipe joints can disrupt the visual flow. Therefore, participants should consider using high-quality finishes and regularly inspecting their work. A meticulous approach can reflect professionalism and elevate project appeal.

Measurements also matter. Research indicates that precise dimensions can improve the fitting of pipes by up to 20%. Any mistakes in this regard can lead to frustrating adjustments later. Smaller projects often suffer from overlooked details, resulting in wasted time and resources. Taking the time to perfect each element not only enhances the project's functionality but also ensures a more attractive outcome.

| Tip Number | Tip Description | Benefits |

|---|---|---|

| 1 | Use Quality Materials | Increases durability and lifespan. |

| 2 | Surface Preparation | Ensures better adhesion of finishes. |

| 3 | Consistent Pipe Layout | Enhances visual appeal and functionality. |

| 4 | Color Coordination | Improves aesthetic value of the project. |

| 5 | Proper Joint Techniques | Enhances integrity and prevents leaks. |

| 6 | Regular Cleaning | Maintains appearance and functionality. |

| 7 | Utilize Pipe Insulation | Improves energy efficiency. |

| 8 | Adhere to Best Practices | Reduces risk of errors and enhances quality. |

| 9 | Finishing Touches | Polishes the final look of the project. |

| 10 | Seek Professional Advice | Provides insights that enhance project quality. |