Made in America

Get Connected With

Email Us

sale@abrvpartsacc.com

Call Us

+1 (626) 448-2100

Made in America

Get Connected With

Choosing the right water fittings for your plumbing needs is a crucial step in ensuring the efficiency and longevity of your plumbing system. As the renowned plumbing expert, John Smith, aptly stated, "Selecting the appropriate water fittings can not only enhance the functionality of your plumbing but also prevent costly repairs down the line." With a myriad of options available in the market, making this choice can be overwhelming for many homeowners and professionals alike.

Water fittings play a vital role in connecting the various components of a plumbing system, influencing both water flow and pressure. From faucets and hoses to pipes and valves, each fitting serves a specific purpose, and their compatibility with one another is essential. Understanding the different types of water fittings available, their materials, and their intended applications is key to making informed decisions.

In this guide, we will explore the essential factors to consider when choosing water fittings, helping you to navigate through the complexities of plumbing requirements. By doing so, you can ensure that your water systems operate smoothly and efficiently, ultimately supporting a sustainable and functional infrastructure.

When identifying your plumbing needs for selecting the right water fittings, the first step is to assess the specific requirements of your plumbing system. Consider factors such as the pressure and flow rate of your water supply, as well as the type of pipes and fixtures already in place. Understanding whether your plumbing is designed for high or low flow can help determine the appropriate fittings you will need. Additionally, evaluate whether you're working on a new installation or upgrading components, as this can influence your choice of fittings.

Another crucial aspect to consider is the intended use of the water fittings. Are they for indoor applications, like sinks and faucets, or outdoor uses, such as irrigation systems? Different environments may require fittings made from various materials that can resist corrosion and withstand temperature changes. Furthermore, be mindful of local building codes and regulations, as complying with these standards is essential for ensuring safe and efficient plumbing systems. By thoroughly assessing your plumbing needs, you can make informed choices that will enhance the functionality and longevity of your plumbing infrastructure.

When selecting water fittings for your plumbing needs, it’s crucial to understand the various types available and their specific applications. Generally, water fittings can be categorized into three primary types: connectors, valves, and fixtures. Connectors are used to join different sections of piping, ensuring a secure link that allows water to flow seamlessly. They come in various shapes and sizes, including couplings, elbows, and tees, each designated for specific plumbing configurations.

Valves, on the other hand, are essential for controlling water flow throughout your plumbing system. They allow you to regulate the pressure and manage shut-off points, which is particularly important during maintenance or emergencies. Common types of valves include gate valves, ball valves, and check valves, each serving distinct functions to enhance the efficiency and safety of your plumbing infrastructure.

Fixtures, such as faucets and showerheads, not only dictate the aesthetics of your plumbing setup but also impact water efficiency, making it important to choose options that align with your consumption goals while still providing the desired functionality.

With a solid grasp of these different types of water fittings, you can make informed decisions that ensure your plumbing system meets your needs effectively and efficiently.

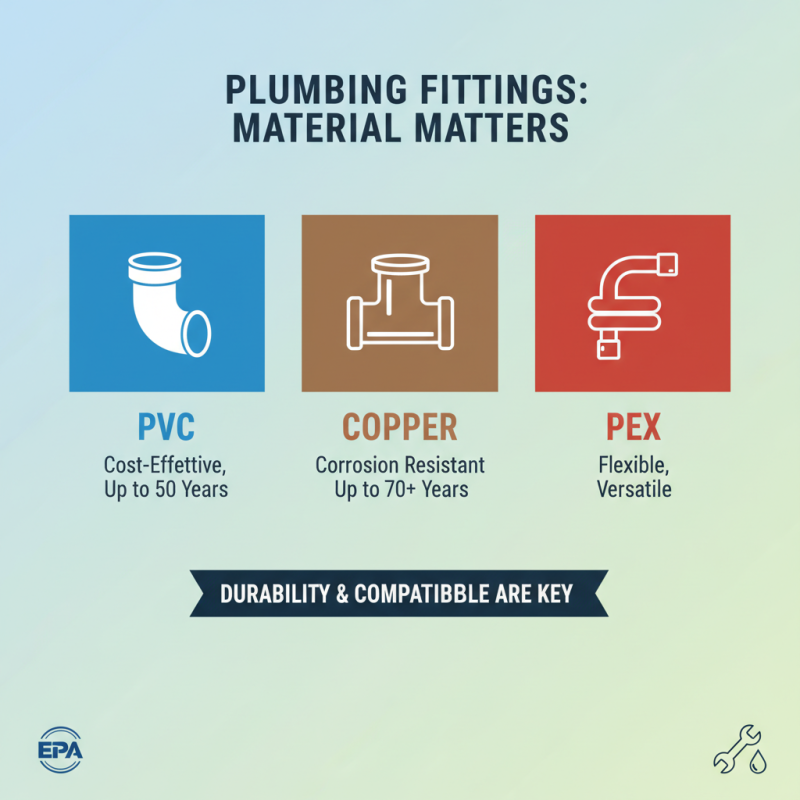

When it comes to choosing the right water fittings for plumbing needs, evaluating material options is crucial for ensuring durability and compatibility. Various materials, such as PVC, copper, and PEX, have different characteristics that make them suitable for specific applications. A report by the U.S. Environmental Protection Agency (EPA) indicates that the average lifespan of PVC fittings can extend up to 50 years, making them a cost-effective choice for many plumbing systems. On the other hand, copper fittings, recognized for their resistance to corrosion and ability to withstand high temperatures, are a traditional favorite, often lasting over 70 years when properly installed.

Compatibility is another important factor when selecting water fittings. According to the American Society of Plumbing Engineers (ASPE), improper material pairing can lead to leaks and eventual system failure. For instance, mixing metal fittings with plastic pipes can result in galvanic corrosion, significantly reducing the lifespan of the installation. Consequently, it is advisable to consult compatibility charts and adhere to local building codes when making material selections. This ensures that the chosen fittings will not only meet current plumbing standards but will also perform well over time, thus preventing costly repairs and ensuring a reliable water supply for the long term.

When selecting water fittings for plumbing systems, understanding water pressure and flow rate requirements is essential. Water pressure, typically measured in psi (pounds per square inch), directly affects the performance of fixtures and appliances. According to industry standards, an optimal residential water pressure ranges from 40 to 60 psi. A pressure exceeding 80 psi can lead to plumbing issues such as leaks and burst pipes. Therefore, it’s crucial to assess your home’s water pressure using a pressure gauge before choosing fittings to ensure they can handle the given pressures without compromising on performance.

Flow rate, measured in gallons per minute (GPM), indicates how much water is delivered through plumbing fixtures. For instance, showers generally require a flow rate of 2.5 GPM, while kitchen faucets may demand up to 2.2 GPM. The U.S. Environmental Protection Agency (EPA) emphasizes the importance of choosing fittings that maintain efficiency without sacrificing comfort, encouraging consumers to opt for products that reduce flow without affecting performance. Choosing the right fittings that correspond with both the ambient water pressure and required flow rate will enhance water efficiency, ensuring adequate performance for daily needs while minimizing potential plumbing problems.

When it comes to installing and maintaining water fittings, proper attention to detail can make a significant difference in the longevity and efficiency of your plumbing system. According to a report by the American Society of Plumbing Engineers (ASPE), almost 70% of plumbing failures derive from improper installation and maintenance of fittings. Therefore, understanding best practices is crucial for homeowners and professionals alike.

**Tips for Installation and Maintenance of Water Fittings**:

First, ensure that all fittings are compatible with your piping materials. Mismatched materials can lead to leaks and increased maintenance costs. For instance, using brass fittings with copper pipes requires careful soldering techniques to avoid corrosion. Secondly, always adhere to the manufacturer’s guidelines regarding torque specifications when tightening fittings. Over-tightening can cause stress fractures, reducing the lifespan of your fittings. Regularly inspecting your fittings for signs of wear and tear is another essential practice; the National Plumbing Foundation recommends at least annual inspections to identify potential issues before they become costly repairs.

Lastly, proper sealing is crucial to prevent leaks. Using high-quality thread sealants and tapes can significantly improve the durability of your fittings. In fact, research from the Plumbing Efficiency Research Coalition indicates that homes utilizing effective sealing methods experience a 25% decrease in water loss due to leaks. By following these installation and maintenance tips, you can secure the efficiency and reliability of your plumbing fittings for years to come.

| Fitting Type | Material | Common Usage | Installation Tips | Maintenance Tips |

|---|---|---|---|---|

| Ball Valve | Brass | Shut-off applications | Ensure correct orientation, use Teflon tape for seals | Regularly check for leaks and exercise valve periodically |

| Compression Fitting | Plastic or Brass | Connecting pipes in tight spaces | Use appropriate tools and adjust compression nut to snug | Inspect for tightness and wear on the ring |

| Elbow Fitting | PVC or Copper | Changing direction of pipe | Ensure proper angle and use appropriate adhesive for PVC | Check for misalignments and possible cracks |

| Coupling | Copper | Joining two pipes | Clean pipe ends, heat the fitting evenly | Inspect joints regularly for corrosion |

| Tee Fitting | PVC or Brass | Branching off a pipe | Ensure all pipes are level and clean | Check branches for pressure fluctuations |