Made in America

Get Connected With

Email Us

sale@abrvpartsacc.com

Call Us

+1 (626) 448-2100

Made in America

Get Connected With

Malleable iron fittings are essential for various construction and plumbing projects. These fittings offer unique advantages that enhance their versatility and strength. According to industry expert John Smith, "Malleable iron fittings are a game changer in piping systems." This highlights the significant impact they have on project efficiency.

One major benefit of malleable iron fittings is their ability to withstand high pressure and temperature. This makes them ideal for both gas and water applications. Their durability ensures fewer replacements and repairs, saving time and costs in the long run. However, one must consider their weight, which can complicate installation in some situations.

Additionally, malleable iron fittings are known for their adaptability. They can be easily welded or joined with other materials. However, improper handling during installation can lead to flaws. It's vital to pay attention to each step of the process. When executed well, these fittings can significantly enhance the integrity of any project.

Malleable iron fittings are gaining popularity in construction. They offer unique benefits that enhance project durability and efficiency. These fittings are known for their strength and flexibility. They can withstand high pressures and resist wear over time. This makes them ideal for plumbing and hydraulic systems. Their ability to absorb stress reduces the risk of breakage.

Another advantage is their ease of installation. Malleable iron fittings can be easily manipulated and shaped to fit specific project needs. This versatility can save both time and labor costs on-site. However, it's crucial to consider that improper handling can lead to issues. Workers need training to avoid complications.

These fittings also resist corrosion, which aids in their longevity. However, they still require maintenance to ensure optimal performance. Regular inspections can prevent unforeseen failures. Although malleable iron is robust, it is not invincible. Addressing its limitations is essential for successful applications.

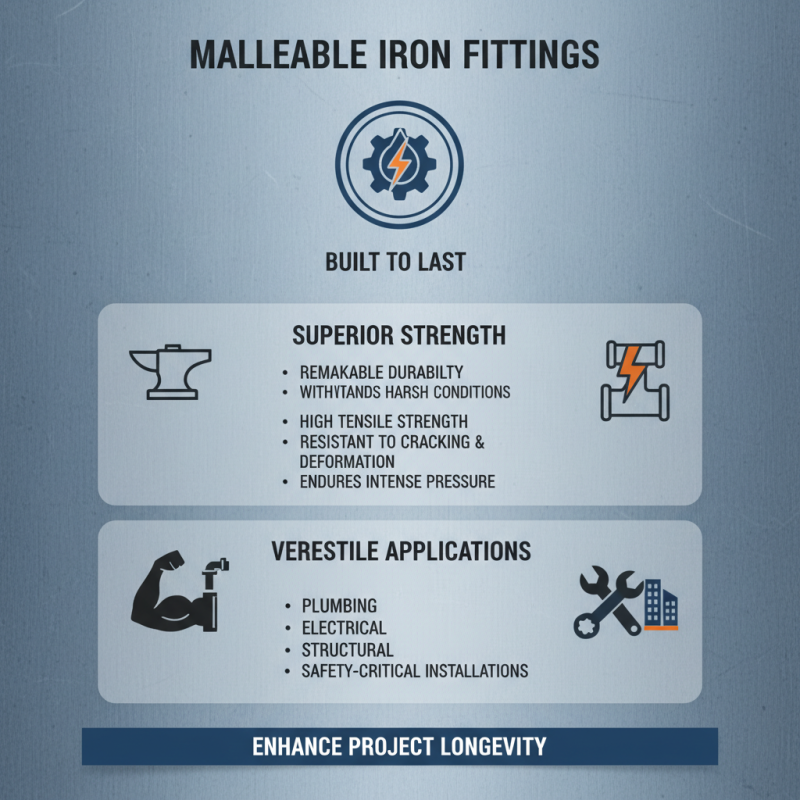

This chart displays the top 10 advantages of using malleable iron fittings in construction projects, highlighting their benefits in strength, durability, and versatility.

Malleable iron fittings are highly regarded for their remarkable durability and strength. This material can withstand harsh conditions. It is often used in plumbing, electrical, and structural applications. Malleable iron has a high tensile strength, making it resistant to cracking and deformation. This quality enhances the longevity of projects. The fittings can endure intense pressure. They do not easily fail under stress, which is crucial in safety-critical installations.

In addition to strength, malleable iron is versatile. It can be molded into various shapes. This adaptability makes it suitable for a range of applications. The fittings are often used in construction and manufacturing. They can also be utilized in both indoor and outdoor environments. The resistance to corrosion in specific conditions adds value. However, attention must be paid to the environment. If exposed to excessive moisture, even malleable iron can rust. Users should consider protective coatings for added safety.

Malleable iron fittings offer significant cost-effectiveness for project budgets. They are often more affordable than other materials in the long run. Their durability means fewer replacements are necessary, saving money over time. These fittings can withstand both high pressure and temperature, reducing maintenance costs significantly.

Using malleable iron can lead to savings on labor as well. Their ease of installation makes them a favorite among workers. Yet, this does not mean that installation is always perfect. Mistakes can happen if proper care isn't taken. Choosing the right type for the project is crucial to avoid issues later.

Another aspect to consider is the recycling value of malleable iron. At the end of their life, these fittings can be repurposed. This can further offset initial costs. However, not every project might prioritize recyclability, leading to wasted materials. Balancing cost and environmental responsibility requires thoughtful planning.

Malleable iron fittings offer impressive corrosion resistance, making them ideal for long-term use. This material excels in environments where moisture and chemicals are prevalent. It withstands rust and degradation better than many alternatives. Projects exposed to the elements can truly benefit from this durability.

However, not all installations go perfectly. While malleable iron resists corrosion, it still may face challenges in highly acidic conditions. It’s crucial to assess the specific environment of your project. Regular inspections can help catch any early signs of wear. Considering these factors can extend the life of your fittings significantly.

In practical scenarios, proper coating can enhance the inherent properties of malleable iron. Sometimes, project managers underestimate the importance of these protective measures. A minor oversight in maintenance can lead to unexpected failures. Ultimately, combining malleable iron’s strengths with good practices yields the best results.

Malleable iron fittings are popular in many projects due to their ease of installation and maintenance. These components are designed for quick assembly, allowing workers to complete tasks efficiently. Their lightweight nature makes handling effortless. This results in faster project timelines without compromising quality.

Maintenance is straightforward as well. These fittings often require minimal upkeep. A simple inspection can identify any wear or damage. When repairs are needed, the parts can be replaced without extensive downtime. This practical approach saves both time and resources in the long run.

However, it's important to consider the environment where these fittings are used. Corrosion can be an issue in certain applications. Regular checks are crucial. Failing to address this could lead to serious inconveniences down the line. Balancing installation speed with regular maintenance is essential for optimal performance.