In today’s industrial landscape, the selection of a Hydraulic Pump and Motor can significantly influence operational efficiency and equipment longevity. According to a recent industry report by MarketsandMarkets, the global hydraulic pump market is projected to reach $13.89 billion by 2027, growing at a CAGR of 5.2%. This growth highlights the increasing demand for high-performance hydraulic systems across various applications, from construction to manufacturing. Choosing the best hydraulic pump and motor is vital as it directly impacts the productivity and reliability of machinery. Employing the right components not only enhances system efficiency but also reduces maintenance costs and downtime, ultimately leading to superior performance. As industries continue to evolve, understanding the advantages of selecting the optimal hydraulic pump and motor becomes essential for businesses seeking to maintain a competitive edge.

When selecting the best hydraulic pump and motor for your applications, understanding the key technical specifications is crucial. Hydraulic pumps and motors come in various designs, including spur and elliptical gear systems, each offering distinct performance characteristics and energy efficiency. Recent experimental studies have employed the Taguchi method to assess the energy consumption of these pumps, highlighting the importance of optimizing design for improved efficiency. Such evaluations help users choose the right system depending on their specific operational needs, minimizing waste and maximizing performance.

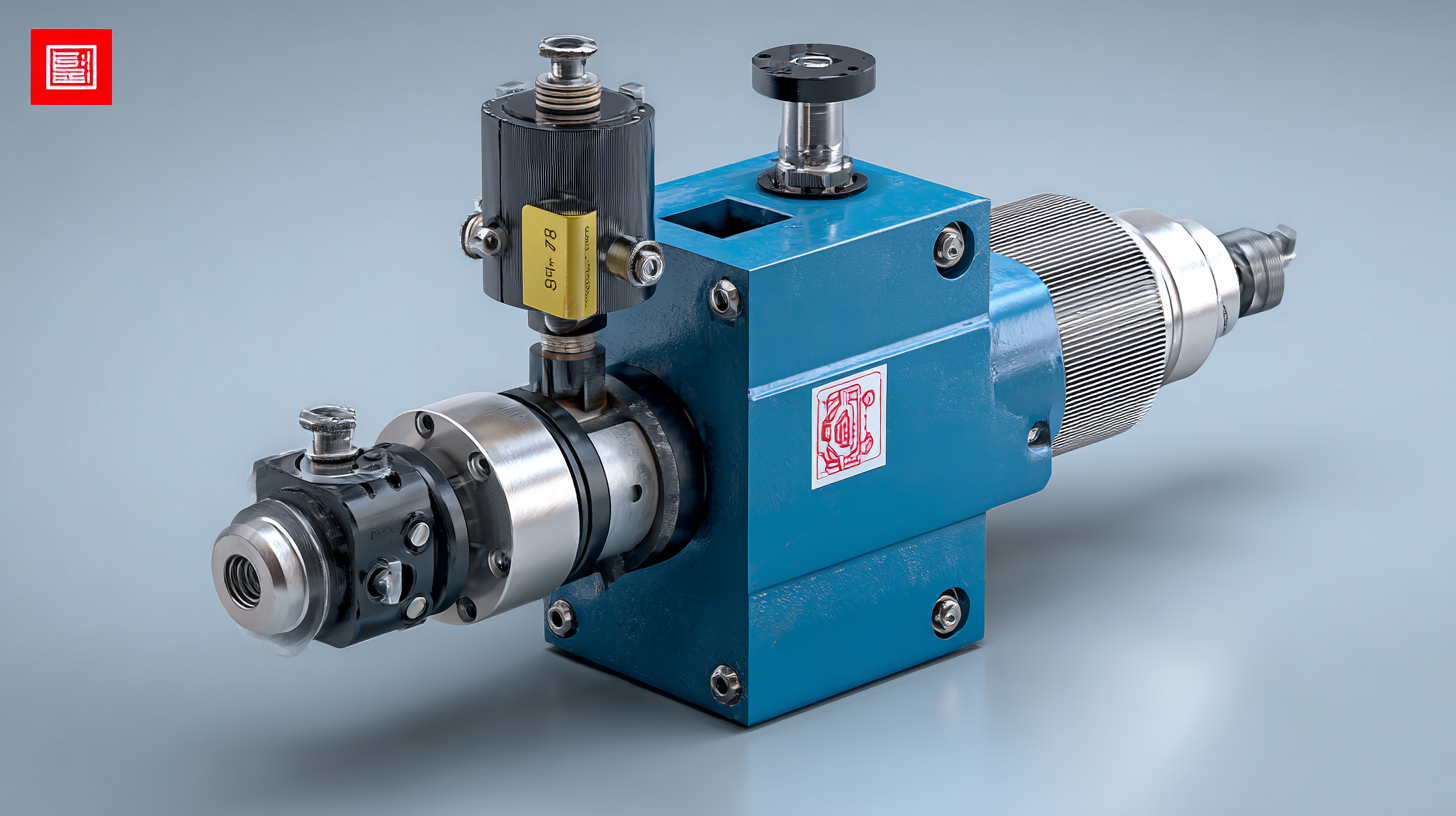

In addition to energy efficiency, the integration of advanced technologies in hydraulic systems has expanded functionality and reliability. For example, modern radial piston motors are increasingly being utilized in mobile equipment, providing robust power sources while accommodating varying operational demands. The development of electric power take-offs (ePTOs) further emphasizes the trend towards electrification in hydraulic applications, ensuring that traditional hydraulic systems continue to play a vital role in electric vehicles. By prioritizing advanced specifications and maintaining these systems with predictive maintenance technologies, users can achieve longer-lasting and more efficient hydraulic solutions.

When selecting hydraulic pumps and motors for various applications, efficiency ratings play a crucial role in ensuring optimal performance. A recent comprehensive review highlights the importance of assessing energy performance gaps in residential buildings, showing that proper evaluation can significantly enhance energy efficiency. The Pumping System Assessment Tool (PSAT) has emerged as a valuable resource, aiding industrial users in assessing the efficiency of their pumping systems and identifying areas for improvement.

Innovative approaches are being developed to optimize energy consumption within hydraulic systems. For instance, the integration of electro-hydraulic systems with variable speed and displacement controls has been shown to yield substantial energy savings. Studies indicate that such configurations can lead to improvements in energy efficiency by an impressive margin—potentially up to 30% depending on the operating conditions. Furthermore, the incorporation of machine learning in the optimization process is paving the way for smarter, more efficient hydraulic systems, enhancing performance while minimizing environmental impact. As industries increasingly prioritize sustainability, selecting hydraulic equipment with high efficiency ratings is not just beneficial—it is essential for maintaining competitive advantage and achieving operational excellence.

When selecting hydraulic pumps and motors, it's crucial to understand the specific needs of your application to ensure optimal performance. Different types of hydraulic pumps and motors are designed for varying operational demands, and understanding these distinctions can lead to significant advantages. For instance, axial piston hydraulic motors and pumps have seen a notable market increase, with projections indicating a rise from $2.9 billion in 2023 to $4.7 billion by 2033, driven by their efficiency and adaptability in various industrial applications.

Comparing top options, the energy efficiency and performance of elliptical gear hydraulic pumps stand out. Recent studies have utilized the Taguchi method to evaluate energy consumption, suggesting that carefully selecting your hydraulic system can yield substantial efficiency gains. Additionally, advancements showcased at events like bauma 2025 highlight the ongoing development of new technologies in hydraulics, emphasizing the importance of staying informed about cutting-edge solutions that align with specific application requirements. This approach not only enhances performance but also contributes to sustainable practices in hydraulic applications.

When selecting hydraulic pumps and motors, understanding power and pressure ratings is crucial for ensuring optimal performance in your applications. The power rating of a hydraulic pump refers to its ability to generate energy efficiently. It's essential to match the pump's power capacity with the requirements of your system, as insufficient power can lead to underperformance and damage, while excessive power may result in unnecessary energy consumption and increased operational costs.

Equally important is the pressure rating, which indicates the maximum pressure the pump can handle safely. This factor is critical for systems that operate under high-stress conditions. Choosing a pump with an appropriate pressure rating not only ensures safety but also enhances reliability and longevity. Inadequate pressure ratings can lead to catastrophic failures, costly downtime, and compromised safety. Therefore, thorough consideration of both power and pressure ratings is vital when selecting hydraulic pumps and motors, ensuring that your equipment runs efficiently and effectively in meeting the demands of your applications.

| Pump Type | Power Rating (HP) | Pressure Rating (psi) | Efficiency (%) | Application |

|---|---|---|---|---|

| Gear Pump | 10 | 3000 | 85 | Construction Equipment |

| Piston Pump | 20 | 4000 | 90 | Heavy Machinery |

| Vane Pump | 15 | 2500 | 82 | Agricultural Equipment |

| Hydraulic Motor | 25 | 3500 | 88 | Marine Applications |

| Axial Piston Pump | 30 | 4500 | 95 | Industrial Automation |

Investing in high-quality hydraulic pumps and motors can lead to significant cost-effectiveness for your operations. Although the initial investment may appear higher than opting for cheaper alternatives, the long-term savings and performance enhancements provided by quality systems cannot be overlooked. Premium hydraulic components often feature superior materials and engineering, which ensure greater durability and reduce the frequency of replacements and repairs. This translates to lower maintenance costs over time, making the investment worthwhile.

Moreover, top-tier hydraulic systems can improve operational efficiency. With reliable performance and enhanced energy efficiency, these systems help reduce energy consumption, leading to further savings on utility bills. A well-functioning hydraulic pump and motor can maintain consistent power output, minimizing downtime and maximizing productivity. As a result, your applications can benefit from smoother operations and ultimately improve return on investment. As companies strive for high productivity while keeping costs down, choosing the best hydraulic systems can be a game-changer in achieving these goals.