Made in America

Get Connected With

Email Us

sale@abrvpartsacc.com

Call Us

+1 (626) 448-2100

Made in America

Get Connected With

In the evolving landscape of pipe manufacturing, efficiency is paramount. The industry faces challenges that require innovative techniques and methods. Traditional approaches may no longer suffice as production demands increase.

Numerous advancements are reshaping how pipes are produced. Techniques such as 3D printing, precision welding, and automation enhance efficiency. However, not all techniques yield the same results. Companies often grapple with balancing quality and speed, leading to mistakes.

The focus must also be on sustainability. Environmentally friendly practices are gaining traction. Manufacturers need to reflect on their production methods. Efficient production should not compromise ethical considerations. Thus, the journey towards the best pipe manufacturing techniques is complex but essential.

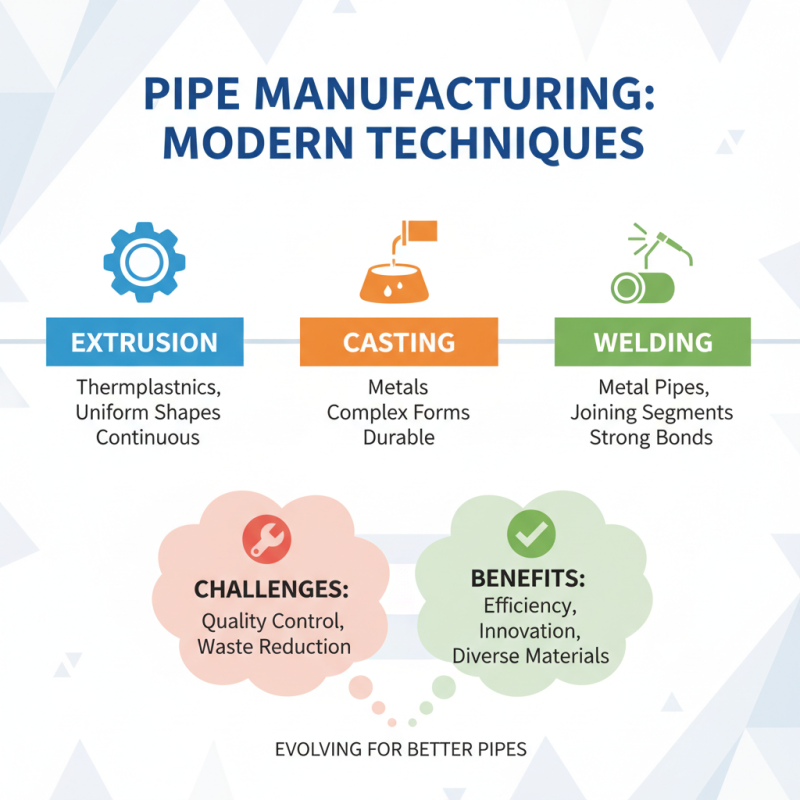

Pipe manufacturing has evolved significantly, focusing on innovative techniques to enhance efficiency. Modern methods include extrusion, casting, and welding. Each technique has its benefits, but challenges remain in maintaining quality and minimizing waste.

Extrusion is popular for producing plastic pipes. It allows for continuous production and precise shapes, yet it can lead to defects if not monitored closely. Studies show that up to 20% of extruded products can have inconsistencies, which impacts overall production quality. Regular calibration and maintenance of machines are essential for reducing these errors.

Casting is another effective method, especially for metal pipes. It allows for complex designs and high durability. However, the process can be energy-intensive, often leading to higher operational costs. Implementing energy-efficient practices can mitigate this issue.

**Tips:** Regular training for staff can improve understanding of these techniques. Quality control processes should be robust and iterative. Assessing supplier materials can also help reduce waste.

In pipe manufacturing, material selection is crucial. Choosing the right materials impacts strength, durability, and production efficiency. Common choices include metals like steel and aluminum, and plastics like PVC and HDPE. Each material has unique properties that affect its performance. For example, steel is strong but heavy. Conversely, plastic pipes are lightweight yet may not withstand high temperatures.

The challenge lies in balancing cost and quality. High-quality materials can increase production costs. Yet, using cheaper materials might lead to higher failure rates. Manufacturers need to consider long-term performance over initial savings. Recycling materials can also be an option, though it may affect the quality.

Another aspect is the environmental impact of production materials. More sustainable options are gaining popularity. However, these materials may require more investment in research and development. Manufacturers must reflect on the lifecycle of their products. This can lead to better choices that align with modern demands. Ultimately, understanding material properties is key for efficient pipe production.

Modern fabrication techniques in pipe manufacturing have evolved significantly. Today’s methods focus on efficiency and precision. Techniques like laser cutting and CNC machining are now commonplace. They help to create pipes with tight tolerances. These technologies can reduce waste and speed up production times. However, the transition to advanced methods can be challenging for some manufacturers.

Welding techniques have also advanced. Automated welding systems enhance consistency in joints, ensuring durability. Yet, the initial investment in automation can be daunting. Not all facilities can adapt quickly. Some still rely on traditional methods, which may lag behind modern standards. This could lead to quality issues and increased production costs.

Moreover, sustainable practices are becoming increasingly important. Techniques that reduce environmental impact are gaining attention. For instance, recycling materials can cut expenses and waste. Yet, not all manufacturers prioritize sustainability. This inconsistency can hinder progress in the industry. Reflection on these issues is essential for future growth.

Quality control is critical in pipe production. It ensures the final products meet industry standards. A recent report indicates that 30% of all manufacturing defects can be traced back to inadequate quality checks. This statistic highlights a significant risk that many manufacturers face.

Implementing rigorous quality control practices can mitigate these issues. For instance, real-time monitoring during production can detect inconsistencies early. Data from industry studies suggest that companies utilizing such methods improve product consistency by up to 25%. However, many organizations still rely on outdated inspection techniques. This reliance on traditional methods can lead to missed defects and decreased satisfaction.

Moreover, testing protocols, such as pressure tests and X-ray inspections, are essential. Yet, not all facilities employ them adequately. A significant gap remains in training personnel on modern techniques. This lack of training can result in half-hearted inspections. The consequences of neglecting quality control are severe, affecting safety and profitability. Addressing these gaps is vital for efficient pipe manufacturing.

Innovative technologies are reshaping pipe manufacturing. Advanced automation plays a crucial role in enhancing efficiency. Robotics streamline assembly lines. They reduce human error, but they require continuous monitoring. Machines can work 24/7, but they need maintenance. Smart sensors alert operators to potential failures, ensuring better productivity.

Another exciting development is additive manufacturing. 3D printing allows customization of pipe designs. This method reduces waste, as only necessary material is used. However, the speed of production can vary. It's not always the fastest option. Traditional methods still dominate in large-scale projects.

Digital twins are also making waves in the industry. They create virtual models of the manufacturing process. This allows for real-time monitoring and adjustments. Problems can be identified before they escalate. Yet, implementing this technology can be complex. Training staff to adapt to new systems takes time and resources. Embracing these innovations is essential, but companies must also address their challenges.

| Technique | Description | Efficiency Gain (%) | Implementation Challenges |

|---|---|---|---|

| 3D Printing | Additive manufacturing technique for water and gas pipes. | 40 | Material limitations and initial cost. |

| Advanced Welding Techniques | Use of laser and ultrasonic welding for pipe joints. | 30 | Requires specialized training. |

| Smart Manufacturing | Integration of IoT for enhanced monitoring and control. | 25 | Cybersecurity risks and technology costs. |

| Material Innovation | Development of composite materials for enhanced durability. | 20 | Higher production costs. |

| Automated Quality Control | Use of AI and machine learning for defect detection. | 35 | Integration with existing systems. |