Made in America

Get Connected With

Email Us

sale@abrvpartsacc.com

Call Us

+1 (626) 448-2100

Made in America

Get Connected With

In the realm of industrial applications, the importance of reliable and efficient connections cannot be overstated, particularly when it comes to pipe couplings. As we look towards the future in 2025, advancements in technology and materials promise to enhance the performance of these critical components. According to a recent market analysis by Global Industry Analysts, the pipe couplings market is projected to reach USD 9 billion by 2025, underscoring the increasing demand for robust and efficient solutions in various sectors, including oil and gas, water treatment, and chemical processing.

John Smith, a renowned expert in the piping industry and author of "Connections that Last," emphasizes the significance of innovative coupling solutions: "The right pipe couplings not only ensure seamless connectivity but also play a crucial role in enhancing overall system efficiency." With such insights guiding the industry's direction, it is essential to explore the various types of pipe couplings available, their applications, and the best practices for their selection and installation. This guide will serve as a comprehensive resource for engineers and industry professionals seeking to optimize their installations and ensure the longevity and reliability of their piping systems.

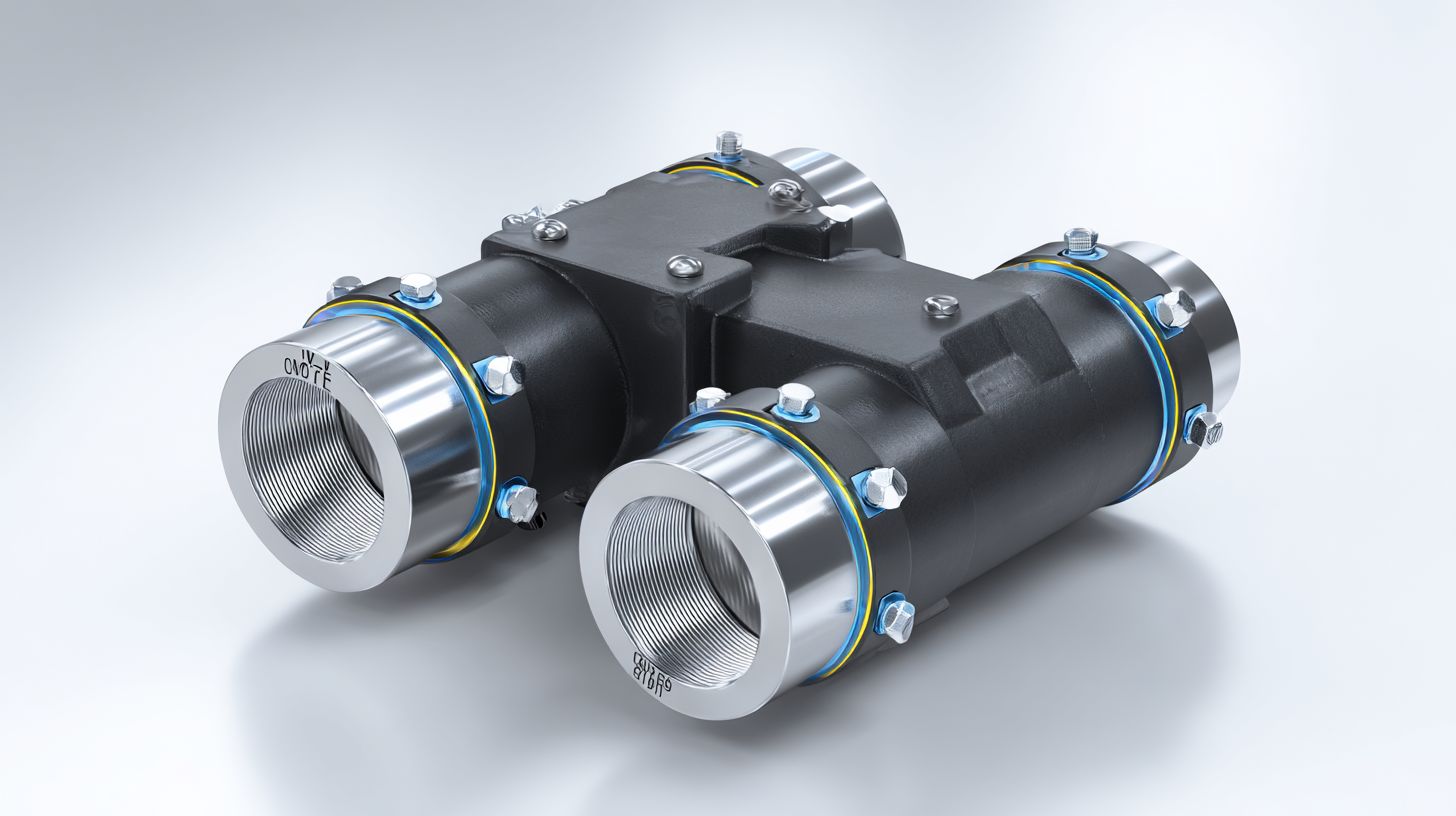

When selecting pipe couplings for industrial applications, several key features must be considered to ensure efficient and reliable connections. According to a recent report by the International Institute of Pipe Coupling Technology, the selection of materials is critical, as it affects not only the coupling's durability but also its resistance to corrosion and extreme temperatures. For example, stainless steel couplings can withstand harsh chemical environments, while PVC options are ideal for low-pressure systems. Always assess the operating conditions to determine the most suitable material for your specific application.

Another crucial aspect is the coupling design, which can greatly influence the ease of installation and maintenance. Many modern couplings come with user-friendly features such as quick-connect mechanisms, which can reduce installation time by up to 40%, according to findings from the Global Coupling Solutions Framework. It is advisable to choose designs that minimize potential leaks and allow for easy disassembly, especially in systems where regular maintenance is required.

Tips:

1. Always consult compatibility charts to ensure the chosen coupling matches the pipe material and diameter.

2. Consider the future expansion of your system; opting for adjustable couplings can enhance flexibility in your infrastructure.

3. Take note of the manufacturer’s certification and testing standards to ensure reliable performance of the couplings under industrial conditions.

When selecting pipe couplings for industrial applications, understanding the materials used can significantly enhance durability and efficiency.

Common materials for pipe couplings include stainless steel, bronze,

PVC, and rubber, each offering unique benefits.

Stainless steel couplings are known for their strength and resistance to corrosion, making them ideal for high-pressure environments.

On the other hand, PVC couplings are lightweight and resistant to chemicals, perfect for various fluid handling applications.

Stainless steel couplings are known for their strength and resistance to corrosion, making them ideal for high-pressure environments.

On the other hand, PVC couplings are lightweight and resistant to chemicals, perfect for various fluid handling applications.

Tip: Consider the operating environment when selecting materials.

For example, if the pipes will carry corrosive substances, opt for materials that provide excellent chemical resistance.

Similarly, for high-temperature applications, materials that can withstand thermal stress are crucial.

Moreover, the choice of coupling can impact the overall efficiency of the pipe system.

Bronze couplings provide reliable connections while resisting seizing and galling, which is essential in applications with frequent disassembly.

Rubber couplings, known for their flexibility, help absorb vibrations and noise, improving the system's longevity.

Tip: Regularly inspect and maintain couplings to prevent leaks and ensure optimal performance.

A well-maintained coupling will not only extend the lifespan of the piping system but also reduce downtime and maintenance costs.

When it comes to installing pipe couplings in industrial applications, adhering to best practices is essential for maintaining system efficiency and integrity. According to a report by the American Society of Mechanical Engineers (ASME), nearly 30% of industrial downtime is attributed to leaks and failures in piping systems, underscoring the importance of proper coupling installation. Ensuring that pipe couplings are correctly aligned and torqued to manufacturer specifications can significantly reduce the risk of leakage and extend the lifespan of piping connections.

Another critical aspect to consider is the compatibility of materials. A study published in the Journal of Pipeline Engineering found that improper material matching can lead to corrosion and premature failure, which affects about 40% of industrial piping systems. Therefore, it’s crucial to select couplings made from materials that are not only suitable for the fluid being transported but also compatible with the existing pipe materials. Regular inspection and maintenance, in conjunction with using high-quality couplings, can enhance operational reliability and minimize costs associated with repairs and replacements.

This chart represents the efficiency of different types of pipe couplings based on their application in industrial settings. The data showcases the percentage of usage in various applications which helps in understanding the best practices for installation.

When choosing pipe couplings for industrial applications, understanding the advantages and disadvantages of various types is crucial. According to a recent report by the International Pipe Association, the demand for efficient coupling solutions has surged, with a projected annual growth rate of 5.2% through 2025. Each coupling type, whether it be mechanical, welded, or flanged, comes with distinct benefits and challenges.

Mechanical couplings, for example, offer ease of installation and flexibility, making them ideal for temporary setups or repairs. However, they may not withstand extreme pressures as effectively as welded couplings, particularly in high-stress environments.

Flanged couplings, though often favored for their strength and durability, require precise alignment and additional space, which can be a limiting factor in cramped industrial settings. On the other hand, welded couplings provide a permanent and robust solution, but they come with higher installation costs and can be time-consuming. It’s vital for engineers to assess application-specific requirements before selecting a coupling type.

Tip 1: Always conduct a thorough analysis of the operational environment to determine which coupling can best handle the temperature and pressure requirements.

Tip 2: Consider the long-term maintenance costs associated with each type of coupling. While some may have lower initial costs, ongoing repairs or replacements can add up.

As the demand for efficient connections in industrial applications surges, the pipe coupling market is positioned for significant growth, driven by several emerging trends. The burgeoning construction activities and advancements in plumbing technologies are notable contributors to this momentum. It is anticipated that by 2025, the market will witness a robust uptick, with research indicating a compound annual growth rate (CAGR) of approximately 5.5% during this period. This growth underscores the urgency for innovative coupling solutions that can meet the evolving demands of modern infrastructure.

Furthermore, urbanization and sustainability are reshaping the landscape of pipe coupling design. The increasing emphasis on eco-friendly materials and energy-efficient installation methods reflects a broader industry shift towards sustainable practices. Industry reports highlight that over 65% of new construction projects now incorporate sustainable plumbing solutions, including advanced pipe coupling technologies. These developments not only facilitate enhanced performance but also contribute to the longevity and reliability of industrial piping systems, aligning with the global push for more responsible resource management in an increasingly urbanized world.